Basic Info.

Model NO.

OEM0987

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.01mm

Customized

Customized

Name

OEM Cold Rolled Stainless Steel Metal Stamping PAR

Technology

15 Years Experience

Service

Ome,Omd

Thickness

0.5--25mm

Certificate

ISO RoHS Ce

Size

Customer′s Request

Finish

Yellow Zinc Plated, Painted etc

Application

Electronic Components, Auto, etc

Surface Treatment

Galvanized/Chroming/Plated/Coated/Painted/Polish,E

Features

Tube/Pipe/Bracket/Square/Round,Ect;

Transport Package

Customized

Specification

customized

Trademark

shengjia

Origin

Dongguan, China

HS Code

7320109000

Production Capacity

100000 Pieces/Year

Product Description

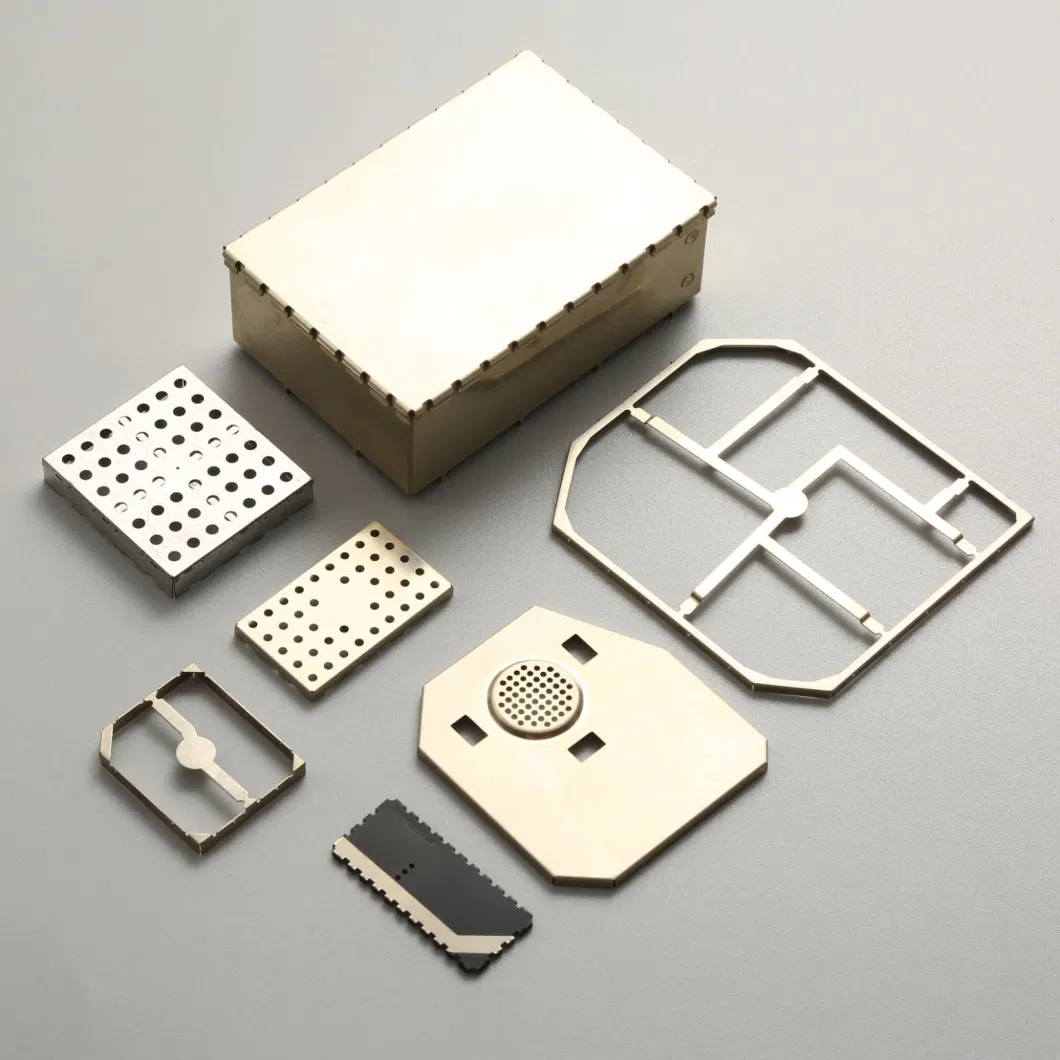

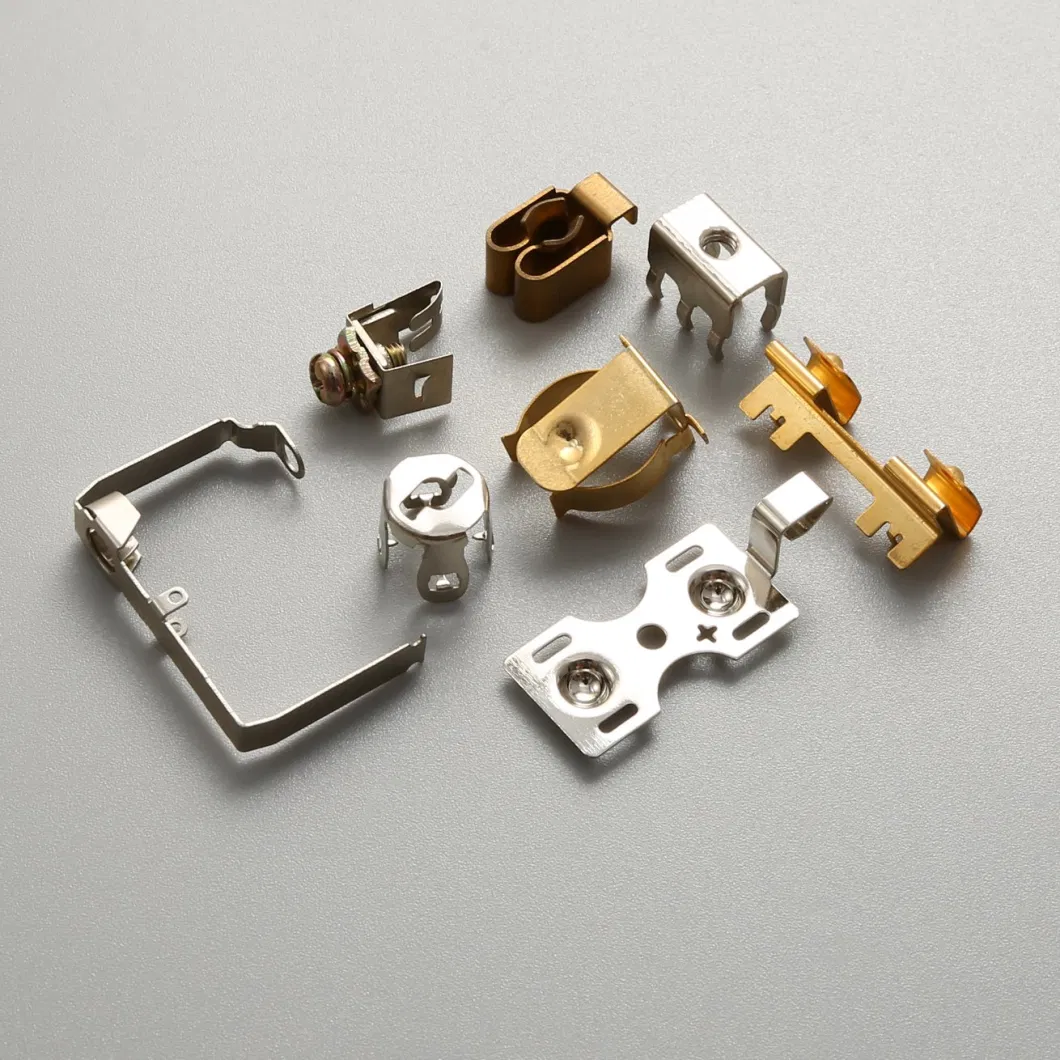

| Product Profile | |

| Material | Stainless Steel/Steel/Aluminum/Alloy/Plastic,ect; |

| Surface treatment | Galvanized/Chroming/Plated/Coated/Painted/Polish,ect; |

| Process | Stamping, procession, forming, etc |

| size | Customer's request |

| Processing Method | Stamping/Bending/Punching/Cutting/Welding/Drilling,ect; |

| Service | ODM, OEM |

| Features | Tube/Pipe/Bracket/Square/Round,ect; |

| Label/Tag | customized |

| Technology | 15 years experience |

| Thickness | 0.5-25mm |

| Finish | Yellow zinc plated, painted, etc |

| Application | Electronical components, Auto, etc |

| MNQ | 500pcs |

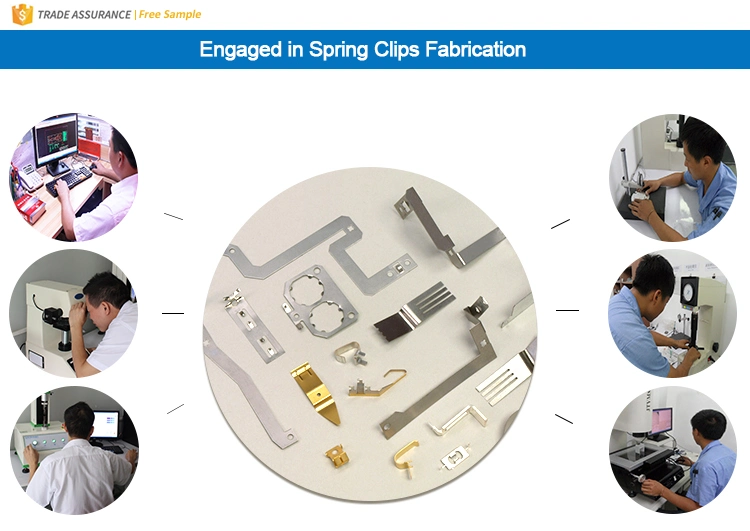

OME Service

1. We provide design assistance and full engineering support

2. We have more than 15 years' experience working with OEM's for aluminum

3. Complete production lines for custom turning, milling, cnc machining sheet metal fabrication

stamping, bending, argon welding and surface finish

4. Anodize and power coating finish with all kinds of customized colors

5. Strict quality control standards with a highly qualified inspection department

6. Continually upgrading and advancing equipment to remain competitive

7. Extensive capacity - We can run 24 hours, 6 days a week

8. Advanced machine tools, CAD/CAM programming software

9. Your CUSTOMER SATISFACTION is our main goal.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control

4) Checking the goods after they are finished---- Final quality control

5) Checking the goods after they are finished-----Outgoing quality control

Company Profile

Dongguan Shengjia Hardware Products Co.,Ltd., established in 2003 as a private enterprise, is a professi

onal manufacturer and supplier integrating designand production of all kinds of precision hardware stamp

ing dies, hardware stampings, aluminum extruded heat-sinks, automatic lath parts, precision springs and

other hardware with experience of more than 15 years.

| Trade information | |

| Trade terms | FOB,CIF,CFR |

| Payment terms | T/T, Western Union,PayPal, L/C |

| MOQ | 300pieces |

| Shipment | DHL, FedEx, UPS, TNT, EMS |

| Port | Shenzhen |

| Sample availability | Yes |

| Sample time | 12-16 working days after payment |

| Lead time | 25-30 working days for bulk order |

| Supply capability | 10,000pcs per day |

| Packing | According to customer's request |

Certifications: ISO 9001:2008,ROHS,CE

Equipment & Tools:

Inspection Tools

CMM, Projection, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, etc.

Machining Equipments

CNC machines, Automatic lathe machine, Stamping Lathes, Milling/ Grinding machine, Drilling/ Boring/

Honing machine,Ultrasonic cleaning machine,etc.

| FAQ |

| Q1:How to know the price? |

| Price is the key issue of customer. To offer the best price for you, the following parameters needed to confirm first: the style of the products, for example, stamping, progreesion, precision, etc, date of delivery and so on, which are the main factors. And the more you order, the cheaper price you will have. |

| Q2:How to confirm the style of the products? |

| If you have your own design, we will produce according to it. If not, just tell us your requirement, then we will make for you thoughtfully. We could always offer you some free samples to select. |

| Q3:What is the quality guaranty after placing order? |

| We are ISO/TS certificated factory,all our works are according to it.All our engineers are with more than 10 years working experience.They are more professional on precision stamping field.We have been approvaled by the thrid party,if you want,i can show you the report. |

Note: For the fast results, when requesting a quote:

1. Please email or fax us your inquiry with as much information as possible.

2. Please include quantities ,material ,thickness, AUTOCAD designs or 3D drawings required.

3. Quotation will be offered ASAP, via fax or email.