- Overview

- Company Profile

Basic Info.

Product Description

Furniture Fitness Equipment Store Metal Fixture Cold Rolled Square /Rectangular / Round Tube

When it comes to creating a successful furniture or fitness equipment store, having the right metal fixtures is crucial. Cold-rolled square, rectangular, and round tubes are some of the most versatile and durable options available. Let's explore why these tubes are a great choice for your store, and what benefits they can offer.

Firstly, let's talk about the manufacturing process. Cold-rolled steel is made by passing the metal through rollers at room temperature, which results in a stronger, more durable material than hot-rolled steel. This means that your fixtures will be less likely to bend or warp over time, even with heavy use.

Square, rectangular, and round tubes all have their own unique benefits. Square and rectangular tubes are great for building frames and structures, as they offer a lot of stability and can hold weight evenly. They're also great for creating custom-sized shelving units or display cases that fit your specific products perfectly.

Round tubes, on the other hand, are ideal for creating curved structures or decorative elements. They're also great for building stands or racks that need to hold cylindrical objects, like weights or yoga mats. And, because they're available in a variety of diameters, you can easily find the perfect size for your needs.

Another benefit of cold-rolled steel is its versatility. These tubes can be cut, welded, and bent into almost any shape you need. This means that you can create custom fixtures that fit your store's unique layout and needs. And, because they're so durable, you can be sure that your fixtures will last for years to come.

Of course, durability isn't the only thing you need to consider when choosing metal fixtures for your store. You also want them to look great and match your store's aesthetic. Thankfully, cold-rolled steel can be finished in a variety of ways to achieve different looks.

For a sleek, modern look, you might choose to leave the steel bare and polished. Or, you might opt for a powder-coated finish in a bold color to make your fixtures stand out. And, if you're going for a more rustic or industrial look, you might choose to leave the steel with a raw, unfinished look.

Finally, let's talk about cost. While cold-rolled steel might be more expensive than other materials, like aluminum or plastic, it offers a lot of benefits that make it worth the investment. Not only is it more durable, but it also looks great and can be customized to fit your specific needs.

And, because cold-rolled steel is so versatile, you might be able to use it for multiple fixtures throughout your store. This can help you save money in the long run, as you won't have to purchase different materials for each fixture.

In conclusion, cold-rolled square, rectangular, and round tubes are an excellent choice for furniture and fitness equipment stores. They offer durability, versatility, and customization options that other materials can't match. And, because they're available in a variety of finishes and sizes, you can create fixtures that perfectly match your store's aesthetic and needs.

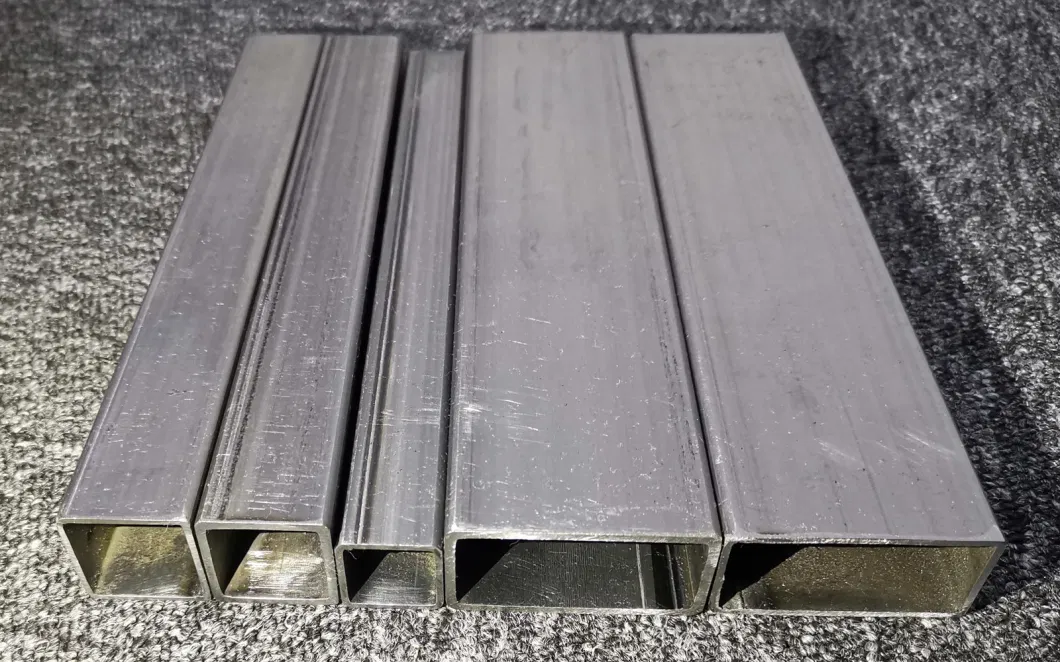

Rectangular Cold Rolled Tube

Rectangular Cold Rolled Tube is a strong, resilient, tough and durable construction material option that can be used for a nearly endless amount of applications. The close tolerances, dense structure and good finishing abilities allow rectangular steel tubing to be utilized either statically or dynamically. Rectangular structural steel tubing can withstand extreme temperatures, pressures and an array of changing climate disparities, while being used in both industrial and domestic settings.

Rectangular Cold Rolled Tube is a strong, resilient, tough and durable construction material option that can be used for a nearly endless amount of applications. The close tolerances, dense structure and good finishing abilities allow rectangular steel tubing to be utilized either statically or dynamically. Rectangular structural steel tubing can withstand extreme temperatures, pressures and an array of changing climate disparities, while being used in both industrial and domestic settings.

Rectangular Steel Tubing Properties & Dimensions

ASTM A500 verified rectangular steel tubing maintains established, clearly defined seams that are not located anywhere within the curvature of the tube. This type of quality control allows for a consistently well-maintained product that is strong and can resist stress from all directions, while being able to easily connect to other structural shapes. A 10.6 radius of corners is also preserved so the corner section of the rectangular steel tubing does not exceed the set parameter of specified wall thickness.

It is worth noting that some of the structural steel items may contain the abbreviation "HSS," which stands for Hollow Structural Section. Essentially, this means that the manufactured product is a square or rectangular steel tube that meets the structural specifications of ASTM A500 Grade B or C. If, however, you see the ASTM A500 designation on a print without a corresponding grade, please ask your engineer for additional clarification, since the minimum tensile strength of Grade C is higher than that of Grade B.

Rectangular Structural Steel Tubing Material Properties

Steel is composed of mainly iron and carbon with smaller amounts of other elements that makeup the minority of the material structure. Nickel and manganese are often added to raw steel compositions to provide increased tensile strength and to promote increased stability within the iron-carbon solution. In addition, chromium increases the hardness of the steel, while the melting temperature, and vanadium also increases hardness while making it less prone to metal fatigue.

Cold Rolled Square and Rectangular Steel Tube

No. | Item | Description |

1 | Short Description | Cold rolled square steel pipes or cold rolled black annealed square tubes is made by the cold rolled sheets or coils, its name comes from the scaly, dark-colored iron oxide coating on its surface. It's used in applications that don't require galvanized steel. |

2 | Steel Grade | Q195, S195 etc. |

3 | Sizes | SHS10X10 to 100X100mm, RHS8X16 to 50X100mm |

4 | Thickness | 0.35mm to 3.0mm |

5 | Yiled Strenth | 195Mpa |

6 | Tenshile Strength | 315-430Mpa |

7 | Length | 5.8/6meters, or other fixed length as reqeusted |

8 | Surface treatment | anti-rust oil |

9 | Pipe Ends | pain ends. |

10 | Packing | Covered by plastic woven sheets, paced in bundles by steel strips, with slings both sides. |

11 | Transportation | by 20/40FT containers or by bulk vessels as per conditon |

12 | Origin | Tianjin, China |

13 | Mill Test Certificate | EN 10204/3.1B |

14 | Third party inspection | SGS/BV |

15 | Payment Term | TT, LC at sight, DP etc. |

16 | Application | furnitures, structural supports, steel frames, mechanical engineering,electricity etc. |