- Overview

- Company Profile

- Our Advantages

- Product Description

- Product Parameters

- Packaging & Shipping

- After Sales Service

- FAQ

Basic Info.

Product Description

Who we are?

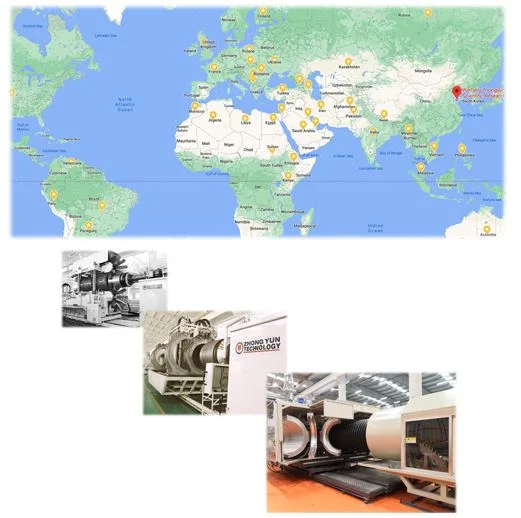

* Top Chinese Corrugated Pipe Machine Manufacturer, based in Weifang City, China, 723 Extrusion Lines sold wordwide.

* Has been solely focused on the Corrugated Pipe Extrusion Line production for 22 years

4 Production Bases

440000 square metre Occupied Area

Serving Customers from 30+ countries

700+ Corrugated Pipe Machines Installed

300+ Empolyees

22 years Focus on Corrugator

As a leading manufacturer of corrugated pipe machinery in China, ZhongyunTech has been focusing on the R&D and manufacturing of corrugated pipe machinery for more than 20 years.

With great innovation vitality, ZhongyunTech has always been committed to help customers continuously reduce pipe production costs and improve their competitive edge, and has won trusts of professional customers in more than 30 countries around the world.

With the vision of becoming a world-class pipe corrugator manufacturer, ZhongyunTech, adheres to the operating philosophy of "continuous innovation, advanced manufacturing and full life services", has been leading the development of pipe corrugator in China. The company has 4 production bases and 1 R&D center, with a total area of 440,000 square meters and more than 300 employees.

By virtue of the world-class management software from SAP Germany, advanced, efficient and standardized management provides a solid backing for ZhongyunTech to manufacture high-precision and high-stability corrugated pipe machines. The company has always attached great importance to manufacturing and quality control; equipped with more than 100 sets of high-precision processing equipment, such as CNC Machines from TOSHIBA, DMG MORI, MIKRON, PAMA; and adopts the world top apparatus to strictly control the dimensional accuracy and position accuracy of each parts, such as Swedish Hexagon 3D coordinate measuring instrument and Leica laser tracker. Manufacture durable and stable corrugated pipe machines with a craftsmanship spirit.

Developed Three Generation Corrugators:

1st Generation: Air Cooling in 2000

2nd Generation: Open Water Cooling in 2004

3rd Genration: Pressurized Water Cooling in 2009

The 1st High Speed Water Cooling Corrugated Pipe Production Line in China is made by ZhongyunTech in 2009.

Customer re-purchasing rate is as high as 90%.

The moulds are compatible between different sizes of corrugators; it makes production organization more flexible. All the corrugated pipe production lines can be utilized more sufficiently to increase the overall capacity of the factory.

Material Saving (lower pipe weight)

ZhongyunTech has installed 700+ sets of corrugated pipe production lines around the world, and in last over 20 years, ZhongyunTech has been paying close attention to customers' feedback and market demand, constantly optimize pipe design so that customers can produce high-quality corrugated pipes with less material.

Perfect In-line Double-layer Socket

ZhongyunTech unique NPM Technology and PBM Technology can produce perfect in-line double-layer socket whose two layers are stick together closely from the starting point to the end point.

- Excellent mechanical structure design is the premise of stable running

- Manufactured with world-class machine tools to guarantee high accurate

- Implement strictly high-grade quality standards with international advanced quality testing apparatus

- Select high-quality suppliers around the world

(1)Mould block temperature control system helps to optimize the pipe quality both appearance and inside.

(2)Stable vacuum molding technology and unique double-layer socket technique ensure that the inner layer and outer layer stick together perfectly.

Higher output, lower production cost

The mould blocks are continuously cooled with pressure water cooling system to achieve higher cooling efficiency and higher production speed of the corrugated pipe machine, so as to lower pipe production cost.

- German SAP's advanced management system and standardized operation ensure consistent quality

- German-Japanese joint venture DMG-MORI flexible line, processing accuracy 0.003mm

- Japan TOSHIBA Gangry Machining Center, repeat accuracy 0.003mm

- Switzerland +GF+Mikron CNC Machine

- Italy PAMA boring milling CNC Machine, Z-axis processing accuracy 0.01mm; X, Y-axis machining accuracy 0.02 mm

- Japan MAZAK flexible lines, processing accuracy 0.003mm

ZhongyunTech has a world-class constant temperature testing room, equipped with Europe (Sweden) advanced 3D coordinate measuring instrument, laser tracker, joint arm measuring instrument and other testing instruments. The Hexagon 3D coordinate measuring instrument has an accuracy of 0.0018mm.

The strict control of manufacturing accuracy is the powerful backing for the long-term high-speed and stable running of ZhongyunTech corrugated pipe machines.

Structure of corrugated pipe extrusion line

Our production line consists of five main parts: extruder, corrugator, cooling bath, automatic sawdust-free cutting machine and unloading device.

| 1 | Model SJPE-120/33B single screw extruder | 1 set |

| 2 | Model SJPE-150/33B single screw extruder | 1 set |

| 3 | Model ZC-1800H high-speed water cooling corrugator | 1 set |

| 4 | Model 1800 spray cooling bath | 1 set |

| 5 | Model 1800 automatic sawdust-free cutting machine | 1 set |

| 6 | Model 1800 unloading device with weighing system | 1 set |

ZhongyunTech Feature of ZhongyunTech corrugated pipe extrusion line

1. Single Screw Extruder

- Automatic feeder with Alarming on lacking of material,

-The hopper is integrally designed for the drying and storing functions, equipped with an automatic intellectual display of temperature control.

- Harden treated screw and barrels for longer life span and durability.

- Efficient shield-style screw with a special blending-melt section greatly improves the plasticizing quality and the output.

- The temperature is controlled by PCC control system with PID temperature controller. The precision of temperature control is±1ºC.

- The complete extrusion line runs full-automatically.

2. Model ZC-1800H pipe corrugator with high-speed water cooling system

-Pressure water-cooling for mould blocks greatly increase the production speed; the maximum speed is 2.5m/min.

- Efficient vacuum system for forming perfect pipes.

-Mould block temperature control system helps to optimize the pipe quality both appearance and inside.

- Easy and quick changeover between different sizes of moulds.

- Pipe Corrugator and extruders are synchronously controlled.

- Toolings (moulds) compatible to ZC-1000H line, ZC-1200H line and ZC-2000H.

3. Model 1800 spray cooling bath

- An effective haul-off device is equipped at the end of the cooling tank to ensure the corrugated pipe conveyed into cutter at a stable speed.

- A powerful blowing dryer is equipped to get rid of the cooling water on the surface of pipes.

4. Model 1800 automatic sawdust-free cutting machine

- Sawdust-free cutting, a hydraulic feed device with high precision can ensure flat and smooth cross-section of the pipes.

- An auxiliary inspection mechanism ensures that the cutter will be placed accurately at the cut position.

5. Unloading Device

- The central height of the unloading device can be adjusted electrically for easy operation.

- The unloading device is equipped with automatic pipe weighting system.

| Pipe Range Min ID | 800mm |

| Pipe Range Max OD | 2000mm |

| Installed gross capacity | 1050kw |

| Normal working power | 400-550kw |

| Maximum production speed | 2.5m/min |

| Maximum Output | 1500kg/hr |

| Overall dimension(L*W*H) | 42m×9.5m×4.6m |

We adopt safe packaging suitable for sea transportation and multimodal transportation, and take comprehensive waterproof measures to prevent the equipment from being damp and rusty. Fix the position of the wooden box when it is loaded into the container to ensure the safe delivery of the equipment to the customer's factory.

Great SERVICE

Pre-sales Support

With 21 years experience and know-how in advanced corrugated pipe production technology, ZhongyunTech is always ready to tailor the specific corrugated pipe solutions for customers all over the world and guide them to succeed, including

- Pipe profile design,

- Plant Layout,

- Material Selection

- Suggestions on Peripheral Equipment Selection

After-sales-service

Full life cycle worry-free service

At ZhongyunTech, We care about the customers experience and service; we put great importance to collecting customers feedback. That is why we keep constant communication with our old customers by our service representatives.

Service Team

ZhongyunTech is proud of her own 15 well-trained and experienced After-Sales Service Engineers, who are providing timely technical support for our customers around the world, day and night. Most of our After-Sales Service Engineers are graduated with mechanical/electrical bachelor degree. And 70% of them have over 5 years professional experience.

Quick response, Minimize the downtime

24-hour on Call, Customers can get in-time service from ZhongyunTech to fix any of their issues.

The fastest supply of high-quality parts to resume the production

Our warehouse dedicated for spare parts is 6000m2. With advanced ERP materials management system, the warehouse can quickly and accurately deliver necessary spare parts to our customers. Less downtime means more output.

Regular on-site Preventative Maintenance

We allocate exclusive service engineer to you immediately after signed contract, A regular on-site inspection will be done every year to prevent problems of the machine in your production.

Q1: Is ZhongyunTech Machinery is Trading Company or a Manufacturer?

A2: ZhongyunTech Machinery is a Manufacturer that has been dedicated to the Corrugated Pipe Machine Production for more than 20 years, developed 1st Chinese high-speed corrugated pipe extrusion line and is the only Chinese Company that is capable of producing corrugated pipes up to OD2000mm. ZhonyunTech owns four manufacturing bases, and you are welcome to visit us in person.

Q2: How long is your delivery time?

A2: In general, it takes about 2 to 5 months. For larger prodution lines, it takes longer.

Q3: Do you provide after-sales service?

A3: Yes, ZhongyunTech has 15 well-trained and experienced After-Sales Service Engineers, providing Full life cycle worry-free service.

Services includes:

* Installation and commissioning of the ZhongyunTech corrugated pipe machines worldwide

* Training of customers' technicians on how to use and maintain the corrugated pipe machines.

* Trouble-shooting by phone, by Internet or on the site.

* General overhaul of corrugated pipe extrusion line

* Relocation of the machines

* Upgrade the machines at customer factory

* Regular Inspection to the corrugated pipe machines

Q4: What extrusion model lines do you currently produce?

A4: Currently we have 7 extrusion model lines,

ZC-180H (producing ID16mm to OD200mm DWC pipes)

ZC-300H (producing ID90mm to OD315mm DWC pipes)

ZC-600H (producing ID100mm to OD630mm DWC pipes)

ZC-1000H (producing ID200mm to OD1000mm DWC pipes)

ZC-1200H (producing ID300mm to OD1200mm DWC pipes)

ZC-1800H (producing ID600mm to OD1800mm DWC pipes)

ZC-2000H (producing ID800mm to OD2000mm DWC pipes)

Besides these 7 model lines, we also produce customized extrusion lines. ZhongyunTech has her own R&D center, from designing to manufacturing, we can bring your requirements into reality.

Q5: We are new to corrugated pipe business, what extrusion line do you recommend to begin with?

A5: Based on our past experience, most of our such customers would choose ZC-600H line. Firstly, This Line does not require as much money as the larger lines. Secondly, it produces the most market required pipe sizes.

Q6: We are using a different brand corrugated pipe produciton line, can we order moulds from you to use them on our machines?

A6: Yes, we can do that. Our moulds are all produced by highly accurate machine tools and experienced technicians. They have a very high cooling efficiency and great quailty, which can help you produce quality corrugated pipes with less materials. Besides moulds, we also costomize Extruder, Corrugator, Cutting Machine based on customers' requirement.

Q7: Can your machine produce in-line socket?

A7: Yes, our machines can produce in-line socket.

Socket is the place where two corrugated pipes join together and also the most likely place where water leakage happens.

Technically, the most difficult to produce part of a corrugated pipe is the socket part. Because it requires the smooth and accurate air change of the built-in Vacuum System.

In 2003, ZhongyunTech developed its own unique NPM Technology and PBM Technology and manufactured the 1st Chinese corrugated pipe extrusion line that can produce in-line Double-layer Socket corrugated pipes.

ZhongyunTech Extrusion Lines can produce perfect Double-layer Sockets, with the inner layer and the outer layer sticking together firmly from the starting point to the end point, Which can achieve a longer service life and avoiding the happening of water leakage.

If you want to know more about this or get one pipe socket sample, welcome to contact us.

Q