Basic Info.

Product Description

Permanent Steel Manufacturing Co.,Ltd (PMC) is your premium supplier and processor of specialty seamless steel pipe, hollow section,high temperature/low temperature steel pipe & fittings - in multiple product forms, including steel plate, bar, tubular and structural forms. In the past, we have been assiduously surpassing our goals step by step in the carbon steel industry. Over the years, perseverance and ardor in our work helped us to carve out a path of success for us and our venerated clients.With state-of-the-art manufacturing processes, contemporary technologies,and proficient services, we consider: offering finest quality-best in class products-at the most advantageous rates, as our forte.

Hollow section members can be circular, square, or rectangular sections, although other shapes are available, such as elliptical. Hollow section is only composed of structural steel per code.These sections are available with anti rust oil coating from inside & outside to ensure safe delivery to end customers.

Square Tube

Standard:

ASTM A500 Grade B,

ASTM A513 (1020-1026)

ASTM A36 (A36)

EN 10210:S235,S355,S235JRH,

S355J2H,S355NH

EN 10219:S235,S355,S235JRH,

S275J0H, S275J2H, S355J0H, S355J2H

Surface conditions:

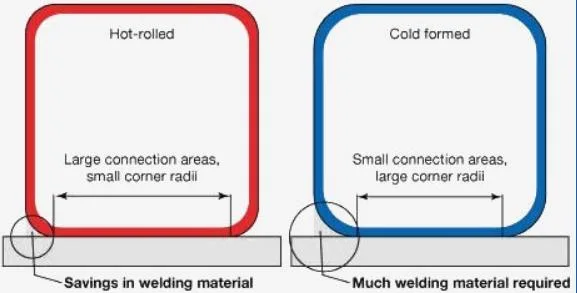

Hot rolled

Cold rolled

Ms Square tube sizes(It can be customized according to customer requirements)

| Size by Inch (diameter) | Thickness | Sizes by MM (diameter) | Thickness |

inch | inch | mm | mm |

1/2" x 1/2" | 0.065" | 16mm×16mm | 0.4mm~1.5mm |

| 3/4" x 3/4" | 0.049" | 18mm×18mm | 0.4mm~1.5mm |

0.065" | 20mm×20mm | 0.4mm~3mm | |

0.083" | 22mm×22mm | 0.4mm~3mm | |

0.120" | 25mm×25mm | 0.6mm~3mm | |

1" x 1" | 0.049" | 30mm×30mm | 0.6mm~4mm |

0.058" | 32mm×32mm | 0.6mm~4mm | |

0.065" | 34mm×34mm | 1mm~2mm | |

0.072" | 35mm×35mm | 1mm~4mm | |

0.083" | 38mm×38mm | 1mm~4mm | |

0.095" | 40mm×40mm | 1mm~4.5mm | |

0.109" | 44mm×44mm | 1mm~4.5mm | |

0.120" | 45mm×45mm | 1mm~5mm | |

1 1/8" x 1 1/8" | 0.035" | 50mm×50mm | 1mm~5mm |

0.049" | 52mm×52mm | 1mm~5mm | |

0.065" | 60mm×60mm | 1mm~5mm | |

0.109" | 70mm×70mm | 2mm~6mm | |

0.120" | 75mm×75mm | 2mm~6mm | |

| 1 1/4" x 1 1/4" | 0.049" | 76mm×76mm | 2mm~6mm |

0.065" | 80mm×80mm | 2mm~8mm | |

0.072" | 85mm×85mm | 2mm~8mm | |

0.083" | 90mm×90mm | 2mm~8mm | |

0.109" | 95mm×95mm | 2mm~8mm | |

0.120" | 100mm×100mm | 2mm~8mm | |

0.135" | 120mm×120mm | 4mm~8mm | |

0.156" | 125mm×125mm | 4mm~8mm | |

0.188" | 130mm×130mm | 4mm~8mm | |

| 1 1/2" x 1 1/2" | 0.049" | 140mm×140mm | 6mm~10mm |

0.065" | 150mm×150mm | 6mm~10mm | |

0.072" | 160mm×160mm | 6mm~10mm | |

0.083" | 180mm×180mm | 6mm~12mm | |

0.109" | 200mm×200mm | 6mm~30mm | |

0.120" | 220mm×220mm | 6mm~30mm | |

0.140" | 250mm×250mm | 6mm~30mm | |

| 0.188" | 270mm×270mm | 6mm~30mm | |

| 0.250" | 280mm×280mm | 6mm~30mm | |

| 1 3/4" x 1 3/4" | 0.065" | 300mm×300mm | 8mm~30mm |

| 0.083" | 320mm×320mm | 8mm~30mm | |

| 0.095" | 350mm×350mm | 8mm~30mm | |

| 0.109" | 380mm×380mm | 8mm~30mm | |

| 0.120" | 400mm×400mm | 8mm~30mm | |

| 0.188" | 420mm×420mm | 10mm~30mm | |

| 2" x 2" | 0.049" | 450mm×450mm | 10mm~30mm |

| 0.065" | 480mm×480mm | 10mm~30mm | |

| 0.083" | 500mm×500mm | 10mm~30mm | |

| 0.109" | 550mm×550mm | 10mm~40mm | |

| 0.120" | 600mm×600mm | 10mm~40mm | |

| 0.145" | 700mm×700mm | 10mm~40mm | |

| 0.165" | 800mm×800mm | 10mm~50mm | |

| 0.188" | 900mm×900mm | 10mm~50mm | |

| 0.250" | 1000mm×1000mm | 10mm~50mm | |

| 0.312" | |||

| 2 1/4" x 2 1/4" | 0.188" | ||

| 0.250" | |||

| 2 1/2" x 2 1/2" | 0.083" | ||

| 0.109" | |||

| 0.120" | |||

| 0.188" | |||

| 0.250" | |||

| 0.312" |

11

| 3" x 3" | 0.083" |

0.120" | |

0.188" | |

0.250" | |

0.312" | |

| 0.375" | |

| 3 1/2" x 3 1/2" | 0.120" |

0.188" | |

0.250" | |

0.312" | |

0.375" | |

| 4" x 4" | 0.083" |

| 0.120" | |

| 0.156" | |

| 0.188" | |

0.250" | |

0.312" | |

0.375" | |

0.500" |

| 4 1/2" x 4 1/2" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

| 5" x 5" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

6" x 6" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

7" x 7" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" |

8" x 8" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

9" x 9" | 0.188" |

| 0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

10" x 10" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

| 12" x 12" | 0.250" |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

14" x 14" | 0.312" |

0.375" | |

0.500" | |

0.625" | |

16" x 16" | 0.312" |

0.375" | |

0.500" | |

0.625" |

Chemical composition of material

| Grade | element | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| Acc.to EN10027/1 | Acc.to EN10027/2 | C% max (Norminal W.T.(mm) | Si% max | Mn% max | P% max | S% max | N% max | |

| and IC 10 | ≤ 40 | |||||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.045 | 0.045 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0.040 | 0.040 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.040 | 0.040 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Mechanical properties of material

| Grade | Yield Strength | Tensile Strength | Elongation |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norm | Yield Strength | Tensile Strength | Min.elogation | Min.percent properties | ||||||||

Acc.to EN10027/1 and IC 10

| Acc.to EN10027/2 | Norminal W.T.mm | Norminal W.T.mm | Longit. | Cross | Test temperature°C | Average min.impact value | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | Norminal W.T.mm | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Equivalent specfications

EN 10210-1 |

NF A 49501 NF A 35501 |

DIN 17100 DIN 17123/4/5 |

BS 4360 |

UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | - | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | - | St E 285 N | - | - |

| S275NLH | - | TSt E 285 N | 43 EE | - |

| S355NH | E 355 R | St E 355 N | - | - |

| S355NLH | - | TSt E 355 N | 50 EE | - |

| S460NH | E 460 R | St E 460 N | - | - |

| S460NLH | - | TSt E 460 N | 55 EE | - |

- block letter "S" means "STEEL FOR STRUCTURAL APPLICATIONS"

- the next fi gure means the minim. yield value required for wall thickness ≤16 mm

- "J2" means impact test value -20° C min. 27 joule

- block letter "H" means "HOLLOW SECTION".

Rectangular Tube:

Standard:

ASTM A500 Grade B,

ASTM A513 (1020-1026)

ASTM A36 (A36)

EN 10210:S235,S355,S235JRH,

S355J2H,S355NH

EN 10219:S235,S355,S235JRH,

S275J0H, S275J2H, S355J0H, S355J2H

Surface conditions:

Hot rolled

Cold rolled

MS Rectangular tube sizes (It can be customized according to customer requirements)

| Size by Inch (diameter) | Thickness | Sizes by MM (diameter) | Thickness |

inch | inch | mm | mm |

1" x 1/2" | 0.065" | 10mm×15mm | 0.6mm~1.5mm |

| 1" x 3/4" | 0.065" | 10mm×20mm | 0.6mm~1.5mm |

| 0.095" | 14mm×21mm | 0.6mm~1.5mm | |

| 1 1/4" x 3/4" | 0.065" | 15mm×30mm | 0.6mm~1.5mm |

| 1 1/2" x 3/4" | 0.065" | 15mm×38mm | 0.6mm~1.5mm |

| 0.120" | 20mm×20mm | 0.6mm~2mm | |

1 1/2" x 1" | 0.065" | 20mm×30mm | 0.6mm~2mm |

0.072" | 20mm×40mm | 0.6mm~2mm | |

0.083" | 20mm×50mm | 0.6mm~2mm | |

0.120" | 22mm×35mm | 0.6mm~2mm | |

2" x 1" | 0.065" | 25mm×40mm | 0.9mm~2mm |

0.083" | 25mm×65mm | 0.9mm~3.75mm | |

0.120" | 30mm×20mm | 1mm~2mm | |

0.188" | 30mm×40mm | 1mm~3.75mm | |

2" x 1 1/4" | 0.065" | 30mm×45mm | 1mm~3.75mm |

0.083" | 30mm×50mm | 1mm~3.75mm | |

2" x 1 1/2" | 0.083" | 30mm×60mm | 1mm~4mm |

0.120" | 40mm×25mm | 1mm~4.5mm | |

| 2 1/2" x 1 1/2" | 0.072" | 40mm×50mm | 1mm~4.5mm |

0.083" | 40mm×60mm | 1mm~4.5mm | |

0.120" | 40mm×80mm | 1mm~5mm | |

0.148" | 40mm×100mm | 1mm~5mm | |

0.188" | 50mm×25mm | 2mm~5mm | |

0.250" | 50mm×30mm | 2mm~5mm | |

| 3" x 1" | 0.083" | 50mm×60mm | 2mm~5mm |

0.120" | 50mm×80mm | 2mm~5mm | |

0.188" | 50mm×100mm | 2mm~5mm | |

| 3" x 1 1/2" | 0.083" | 60mm×30mm | 2mm~6mm |

0.120" | 60mm×40mm | 2mm~6mm | |

0.188" | 60mm×80mm | 2mm~6mm | |

| 0.250" | 70mm×50mm | 2mm~6mm | |

3" x 2" | 0.065 | 80mm×30mm | 2mm~8mm |

0.083 | 80mm×40mm | 2mm~8mm | |

0.125 | 80mm×60mm | 2mm~8mm | |

0.188 | 80mm×100mm | 2mm~8mm | |

0.250 | 100mm×50mm | 2mm~8mm | |

3" x 2" | 0.083" | 120mm×60mm | 2.5mm~10mm |

0.120" | 120mm×80mm | 2.5mm~10mm | |

0.188" | 140mm×60mm | 2.5mm~10mm | |

0.250" | 140mm×80mm | 2.5mm~10mm | |

| 0.312" | 150mm×100mm | 2.5mm~12mm |

4" x 1 1/2" | 0.120" | 160mm×80mm | 2.5mm~12mm |

0.188" | 180mm×150mm | 2.5mm~12mm | |

| 4" x 2" | 0.083" | 200mm×100mm | 4mm~12mm |

0.120" | 200mm×150mm | 4mm~12mm | |

0.188" | 220mm×140mm | 4mm~12mm | |

0.250" | 250mm×150mm | 6mm~12mm | |

0.312" | 250mm×100mm | 6mm~12mm | |

0.375" | 250mm×200mm | 6mm~30mm | |

4" x 2 1/2" | 0.188" | 300mm×100mm | 6mm~30mm |

0.250" | 300mm×150mm | 6mm~30mm | |

| 4" x 3" | 0.083" | 300mm×200mm | 6mm~30mm |

0.120" | 300mm×250mm | 6mm~30mm | |

0.188" | 400mm×250mm | 8mm~30mm | |

0.250" | 400mm×300mm | 8mm~30mm | |

0.312" | 450mm×200mm | 8mm~30mm | |

0.375" | 450mm×250mm | 8mm~30mm | |

| 4 1/2" x 2 1/2" | 0.188" | 400mm×300mm | 8mm~30mm |

0.250" | 400mm×350mm | 8mm~30mm | |

| 5" x 2" | 0.120" | 500mm×200mm | 10mm~30mm |

0.188" | 500mm×250mm | 10mm~30mm | |

0.250" | 500mm×300mm | 10mm~30mm | |

0.312" | 500mm×350mm | 10mm~30mm | |

0.375" | 500mm×400mm | 10mm~30mm | |

| 5" x 2 1/2" | 0.120" | 500mm×450mm | 10mm~30mm |

0.188" | 600mm×200mm | 10mm~28mm | |

0.250" | 600mm×400mm | 10mm~28mm | |

| 5" x 3" | 0.188" | 600mm×500mm | 10mm~28mm |

0.250" | 800mm×400mm | 10mm~28mm | |

0.312" | 800mm×600mm | 10mm~28mm | |

0.375" | 800mm×700mm | 10mm~28mm | |

0.500" | 1000mm×400mm | 10mm~28mm | |

5" x 4" | 0.188" | 1000mm×500mm | 10mm~28mm |

0.250" | 1000mm×600mm | 10mm~28mm | |

0.312" | 1000mm×800mm | 10mm~28mm | |

0.375" | |||

6" x 2" | 0.120" | ||

0.188" | |||

0.250" | |||

0.312" | |||

0.375" |

6" x 3" | 0.120" |

0.188" | |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

| 6" x 4" | 0.120" |

0.188" | |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

| 7" x 3" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

7" x 4" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

| 7" x 5" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

| 8" x 2" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

| 8" x 3" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" |

8" x 4" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

8" x 6" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

| 9" x 3" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

9" x 7" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

10" x 2" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

10" x 3" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

10" x 4" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

10" x 5" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" |

10" x 6" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

| 10" x 8" | 0.188" |

0.250" | |

0.375" | |

0.500" | |

0.625" | |

| 12" x 2" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

12" x 3" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

12" x 4" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

| 0.500" | |

| 0.625" |

| 12" x 6" | 0.188" |

0.250" | |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

| 12" x 8" | 0.250" |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

| 12" x 10" | 0.250" |

| 14" x 4" | 0.250" |

0.312" | |

0.375" | |

0.500" | |

| 14" x 6" | 0.250" |

0.312" | |

0.375" | |

0.500" | |

14" x 10" | 0.250" |

0.312" | |

0.375" | |

0.500" | |

0.625" | |

| 16"x 4" | 0.312" |

0.375" | |

0.500" | |

16" x 8" | 0.250" |

0.312" | |

0.375" | |

0.500" | |

| 16" x 12" | 0.312" |

0.375" | |

| 0.500" | |

| 0.625" |

| 18" x 6" | 0.312" |

0.375" | |

0.500" | |

| 20" x 4" | 0.312" |

0.375" | |

0.500" | |

| 20" x 8" | 0.312" |

0.375" | |

0.500" | |

| 20" x 12" | 0.312" |

0.375" | |

0.500" | |

0.625" |

| Grade | element | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

Mechanical properties of material

| Grade | Yield Strength | Tensile Strength | Elongation |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norm | Yield Strength | Tensile Strength | Min.elogation | Min.percent properties | ||||||||

Acc.to EN10027/1 and IC 10

| Acc.to EN10027/2 | Norminal W.T.mm | Norminal W.T.mm | Longit. | Cross | Test temperature°C | Average min.impact value | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | Norminal W.T.mm | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275J0H | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355J0H | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Equivalent specfications

EN 10210-1 |

NF A 49501 NF A 35501 |

DIN 17100 DIN 17123/4/5 |

BS 4360 |

UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | - | Fe 360 B |

| S275J0H | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355J0H | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | - | St E 285 N | - | - |

| S275NLH | - | TSt E 285 N | 43 EE | - |

| S355NH | E 355 R | St E 355 N | - | - |

| S355NLH | - | TSt E 355 N | 50 EE | - |

| S460NH | E 460 R | St E 460 N | - | - |

| S460NLH | - | TSt E 460 N | 55 EE | - |

- block letter "S" means "STEEL FOR STRUCTURAL APPLICATIONS"

- the next fi gure means the minim. yield value required for wall thickness ≤16 mm

- "J2" means impact test value -20° C min. 27 jaoule

- block letter "H" means "HOLLOW SECTION".

PMC has always inculcated and followed sten quality standards for all of its manufacturing processes. All the materials used by PMC are of premium quality and compatible with latest machineries and manufacturing technologies. The technical and commercial quality guidelines of PMC are set to high standards. A quality control team supervises quality assurance and control aspects along with the entire process system by recognizing and associating with the quality circle. The quality control tests are conducted regularly in order to maintain a consistent and uniform product quality.

Tests of Hollow Section:

Chemical Component Analysis

Mechanical Properties - Elongation, Yield Strength, Ultimate Tensile Strength

Technical Properties - DWT Test, Impact Test, Blow Test, Flattening Test

X-ray Test

Exterior Size Inspection

Hydrostatic Test

FAQ

Q1. What are your company's main products ?

A2: Our main products are carbon steel seamless pipe, welded pipe, hollow section, pipe fittings(flange,elbow, tee, reducer,nipple etc.), and sheets, pipes, coils, strips, bars and channels.

Q2. What are the advantages of your company ?

A2: Offering finest quality-best in class products-at the most advantageous rates, as our forte.

Q3. How do you control quality ?

A3: A quality control team supervises quality assurance and control aspects along with the entire process system by recognizing and associating with the quality circle. The quality control tests are conducted regularly in order to maintain a consistent and uniform product quality.

Q4. How many coutries you already exported ?

A4: Exported to more than 50 countries mainly from Middle East, Russia, United States, Canada, Italy, Germany, Australia, Egypt, Japan, Indonesia, Bangladesh, Turkey, India, etc.

Q5. Can you provide sample ? Do you support OEM ?

A5: Yes. Small samples in store can be provided for free. Customized samples will take about 2-3days.

Q6: What's your payment terms ?

A6: By T/T(30% deposit in advance, balance 70% before shipment),, L/C after sight 30~120 days. Western Union, Paypal, or Trade Online.