Basic Info.

Product Description

Can be customized Spray Dyer Line

1. Machine introduction Mainly applicable to colleges and universities, research institutes and food and pharmaceutical industry laboratory production of trace particles of powder, for all solutions such as emulsions, suspensions with broad-spectrum applicability, suitable for heat-sensitive substances such as biological products, biological pesticides , Enzyme preparations, etc., because the material is only sprayed into the mist when the size of particles by the high temperature, it is only instantaneous heat, to keep these active materials in the dry after the maintenance of its active ingredients are not destroyed.

The whole machine is made of 304 stainless steel and the nozzle is made of 316 stainless steel.

2. Machine features

1.Original imported nozzle, high efficiency.

2.Color LCD touch screen parameters display: air inlet temperature / outlet temperature / peristaltic pump speed / air volume / pass needle frequency.

3.With a nozzle cleaner (through the needle), when the nozzle is blocked, it will automatically clear the frequency of the needle can be automatically adjusted.

4.Shutdown protection function: only need to stop when the shutdown button, the machine in addition to the fan immediately stop running, to ensure that the device will not be due to misuse (forced off the wind turbine) caused by heating part of the burn.

5.The spray, drying and collection system is made of a transparent, high-quality, high-borosilicate heat-resistant glass material to allow the drying process to proceed in a non-polluting environment.

6.Two fluid spray atomization structure, compact design, no ancillary equipment. The same time as the above-

7.dry temperature control design using real-time control PID temperature control technology, so that the whole temperature zone temperature control accuracy, heating temperature control accuracy ± 1 ºC.

8.In order to keep the sample pure, equipped with air inlet filter.

9.The amount of feed can be adjusted by feed peristaltic pump, the minimum sample volume up to 30ml.

10.dry finished powder, the particle size is more uniform, more than 95% of the dry powder in the same particle size range.

11.For the sticky material, with a nozzle cleaner (through the needle), when the nozzle is blocked, it will automatically clear the frequency of the needle can be automatically adjusted.

3. Technical parameters&Quotation

Model | HT-RY1500 | ||

Inlet Temperature | 30 ºC ~400ºC | ||

Outlet Temperature | 30 ºC ~200ºC | ||

Water Evaporation Capacity | 1500mL/H ~ 2000ml/h | ||

Max Inlet Amount | 2000ml/h | ||

Min Inlet Amount | 50mL | ||

Temperature control accuracy | ±0.5ºC | ||

Average drying time | 0.8~1.0S | ||

Power | 3.8KW /220V(can be customed) | ||

Dimension | 600*800*1400mm | ||

Material | Carbon steel casing | All Stainless steel | |

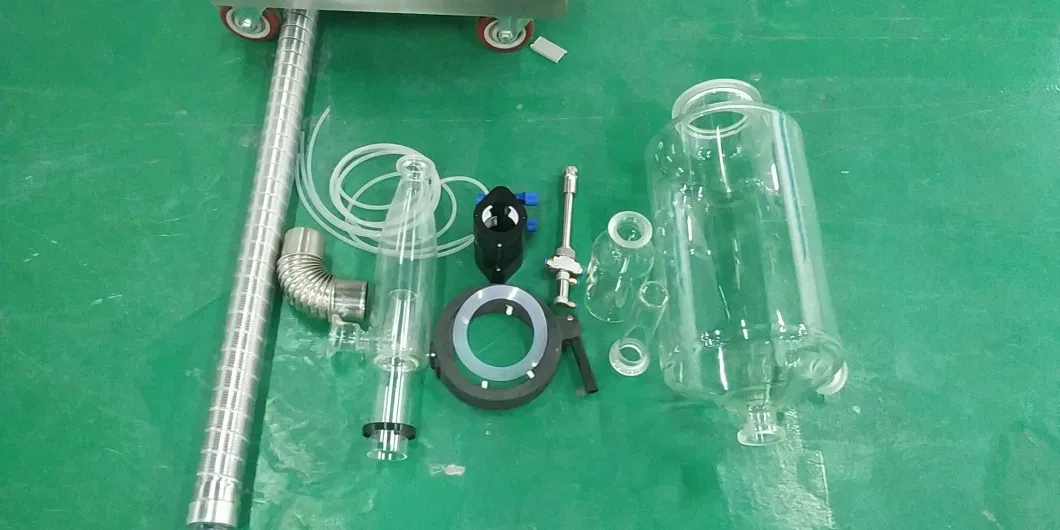

4.Fittings | ||

Dry machine | 1/set |

|

Air compressor | 1/set |

|

Glass drying room | 1/set |

|

Glass cyclone separator | 1/piece |

Glass sample collection bottle 500ML | 1/piece |

Glass samples collect cold traps | 1/piece |

Medical grade feeding tube | 1.5m |

Spray pistol | 1/piece |

Clamp | 1/set |

PTFE gasket | 1/piece |

4.Company Certificate:

5.Our Customs