Basic Info.

Model NO.

A106 /A53/A213/312/A60/API 5L

Usage

Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose

Section Shape

Round

Types

Carbon Steel

MOQ

1 Ton

Process Service

Bending, Welding, Decoiling, Punching, Cutting

Transport

CFR CIF Fob

Transport Package

Standard Packaging

Specification

2.11-59.54mm(Thickness)

Origin

China

HS Code

7304192000

Production Capacity

5000ton Per Month

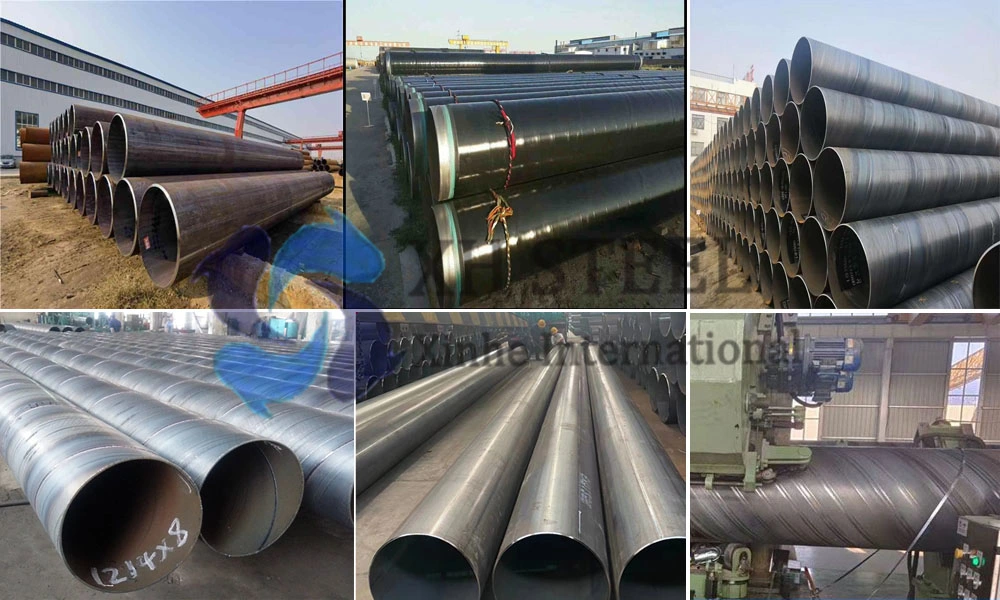

Product Description

Carbon steel pipes are divided into two categories: hot-rolled and cold-rolled (drawn) steel pipes.

Hot-rolled carbon steel pipes are divided into general steel pipes, low and medium pressure boiler steel pipes, high pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes and other steel pipes.

In addition to general steel pipes, low and medium pressure boiler steel pipes, high pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, and other steel pipes, cold-rolled (pulled) carbon steel pipes also include carbon thin-walled steel pipes, alloy thin-walled steel pipes, non-ferrous steel pipes, etc. Rust thin-walled steel pipe, special-shaped steel pipe. The outer diameter of hot-rolled seamless pipes is generally greater than 32mm, and the wall thickness is 2.5-75mm. The outer diameter of cold-rolled seamless pipes can reach 6mm and the wall thickness can reach 0.25mm. The outer diameter of thin-walled pipes can reach5mm and the wall thickness is less than 0.25mm. Cold rolling has higher dimensional accuracy than hot rolling.

General carbon steel pipe: It is made of 10, 20, 30, 35, 45 and other high-quality carbon steel 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot-rolled or cold-rolled. Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid transportation pipelines. 45, 40Cr and other medium carbon steel seamless pipes are used to manufacture mechanical parts, such as the stressed parts of automobiles and tractors. Generally, carbon steel pipes are used to ensure the strength and flattening test. Hot-rolled steel pipes are delivered in hot-rolled or heat-treated state; cold-rolled steel pipes are delivered in heat-treated state.

| Product Name | carbon steel pipe/line pipe | |

| Size | O.D | 21.3-750mm |

| W.T | 2-50mm | |

| Length | 1-12m , customized | |

| Standard | AISI,ASTM,GB,DIN,BS,JIS | |

| Color | coating /black | |

| Technique | Cold/Hot Rolled | |

| Section Shape | Round | |

| Main Market | Southeast Asia, Middle East, Australia,USA,South America,Africa | |

| Productivity | 5000 Tons/month | |

| Packing | Standard bundle package Beveled end or as per request | |

| Surface Treatment | Black Painted, PE Coated, Galvanized or Customized all available | |

| Date of Delivery | According to The Specifications And the Quantities Of Each Contract,Time Start To Begin When We confirm the Date or L/C | |

| Remarks | 1.Payment Terms T/T, L/C,West Union | |

| 2.Trade Term:FOB/CFR/CIF , discussible | ||

| 3.Minimum Quantity of Order: 1 Ton | ||

| 4.Delivery Time: 3-5 days after receipt of deposit | ||

X60 line pipe is used for oxygen, water and oil transportation pipes in the petroleum and natural gas industries.

| Standard | Grade | (%) | CEV(%) | |||||||

| C | Si | Mn | P | S | V | Nb | Ti | |||

| API SPEC 5L GB/T9711.2 | B | ≤0.16 | ≤0.40 | ≤1.10 | ≤0.020 | ≤0.010 | - | - | - | ≤0.42 |

| X42 | ≤0.17 | ≤0.40 | ≤1.20 | ≤0.020 | ≤0.010 | ≤0.05 | ≤0.05 | ≤0.04 | ≤0.42 | |

| X52 | ≤0.20 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.10 | ≤0.05 | ≤0.04 | ≤0.45 | |

| X60 | ≤0.21 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.15 | ≤0.05 | ≤0.04 | | |

| X65 | ≤0.16 | ≤0.45 | ≤1.60 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 | |

| X70 | ≤0.16 | ≤0.45 | ≤1.70 | ≤0.020 | ≤0.010 | ≤0.06 | ≤0.05 | ≤0.06 | ≤0.45 |

| Standard | | Tensile Strength(MPa) | Yield Strength(MPa) | Yield to Strength Ratio | Elongation(%) | 0°C impact energy Akv(J) | Heat treatment status |

| API SPEC 5L GB/T9711.2 | | ≥415 | 245~440 | ≤0.80 | 22 | ≥40 | Normalizing |

| X42 | ≥415 | 290~440 | ≤0.80 | 21 | ≥40 | Normalizing | |

| X52 | ≥460 | 360~510 | ≤0.85 | 20 | ≥40 | Normalizing | |

| X60 | ≥520 | 415~565 | ≤0.85 | 18 | ≥40 | Normalizing | |

| X65 | ≥535 | 450~570 | ≤0.90 | 18 | ≥40 | Quenching+Tempering | |

| X70 | ≥570 | 485~605 | ≤0.90 | 18 | ≥40 | Quenching+Tempering |

Q1. What is your payment terms?

TT OR LC.

Q2. Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time .Honesty is our company's tenet.

Q3. Do you provide samples ? is it free or extra ?

The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q4. How can I get a quotation from you ?

You can leave us message, and we will reply you at any time. And you can also find our contact information on contact page.

Q5.How can you garantee what I got will be good ?

We are factory with 100% predelivery inspection which garantee the quality. We also accept testing by third-party testing agencies.