- Overview

- Product Description

- Product Parameters

- Packaging & Shipping

- Company Profile

Basic Info.

Model NO.

CMT

Warranty

12 Months

Metal Color

Copper

Customized

Customized

Condition

New

Transport Package

Plastic Film and Wooden Box

Origin

China

Production Capacity

5000 PCS/Year

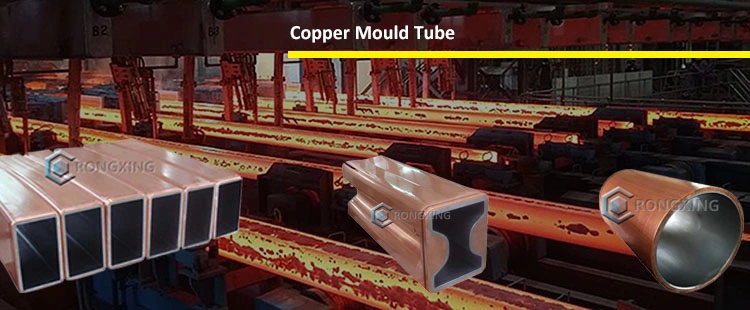

Product Description

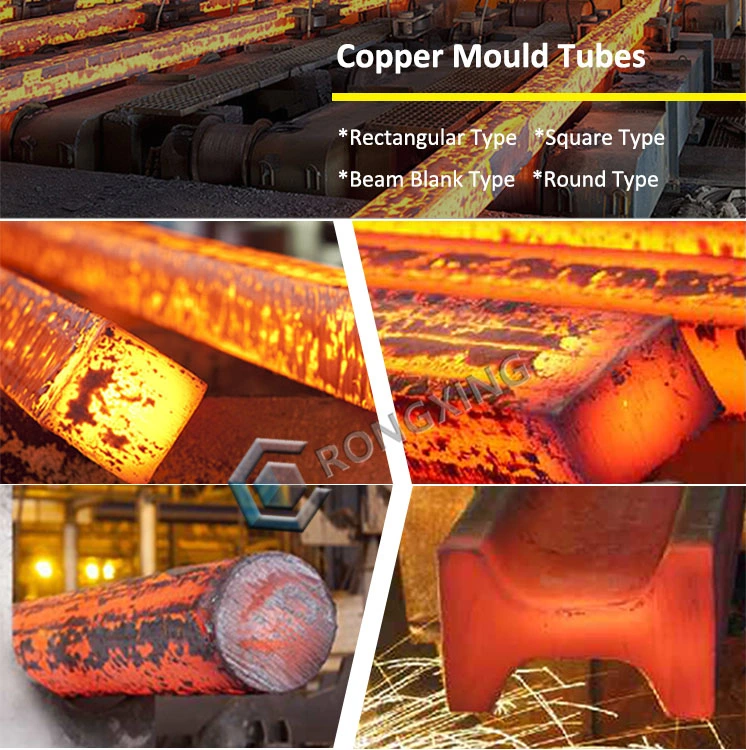

| Copper Mould Tube for CCM Include:square copper mould tube, rectangular copper mould tube, round copper mould tube, beam blank copper mould tubes and other non-standard copper mould tubes. Production Process: Melting & Casting --- Hot Extrusion/Forging --- Cold Drawing --- Tapering --- Machining --- Electroplating --- Machining after Electroplating --- Final Inspection --- Packing |

| Raw Material of Crystallizer Copper Tube 1. Cu-DHP: For mould tubes section size below 180x180mm and round tubes below Dia.150mm. 2. Cu-Ag: For mould tube section size above 180x180mm and round tubes above Dia.150mm 3. Cu-Cr-Zr: For beam blank mould tubes These materials have different levels of hardness and thermal conductivities. Please contact us to get best plan. |

| Product Name | Size | Thickness | Length | Radius |

| Square Copper Tubes | 50x50-650x650 | 6-50 | 602-1100 | 3000-17000 Or straight |

| Round Copper Tubes | φ110-φ1500 | 10-50 | 602-900 | 5000-17000 Or straight |

| Rectangle Copper Tubes | (100-500)x650 | 6-50 | 602-1100 | 3000-17000 Or straight |

| Beam Blank Copper Mould Tubes | 535-150x120-70 | 12-50 | 700-1016 | 6000-14000 |

| Non-standard Copper Mould Tubes | 535-150x120-70 | 12-50 | 700-1016 | 6000-14000 |

| Advantages of Rongxing Copper Mould Tubes: • Uniform shell growth,Optimum billet quality • Reliable quality Created copper mould tube with good raw materials, produce copper mould tube products based on industry norms and high standards. • Special coatings. Increase erosion resistance and service life We always dedicated to research special coatings. The mould tubes can be coated with our different types of internal surface coating: Cr, Ni-Co, Ni-Fe, Ni-Co-Cr. The coating thickness has been controlled in the best range. • Customized and low cost. You might order copper mould tube according to your industrial needs. We help you to produce these products on your limited budget to access on your field. |

| 1. Are you Factory or Trading? We are factory with ISO 9001:2015 certified 2. How to guarantee quality? Always a pre-production sample before mass production; Always final Inspection before shipment; 3. What is your payment service? Accepted Delivery Terms: FOB, CFR, CIF, EXW; Accepted Payment Currency: USD, EUR, CNY; Accepted Payment Type: T/T, L/C; More requirements,Please send inquiry to us,let's confirm them directly. |