Basic Info.

Model NO.

JT1-1

Material

Carbon Steel

Material Feature

Oil Resistant

Certification

ISO9001:2008, CE

Energy Saving

Energy Saving

Warranty

1 Year

Color

Black

Customized

Customized

Condition

New

After-sales Service

One Year

Capacity

5-10t/H

Motor Power

1.5kw

Transport Package

Nude Package

Specification

1100*500*430mm

Trademark

WKD

Origin

China

HS Code

8474202000

Production Capacity

500 Sets/Month

Product Description

Product Description

Rectangle Compartment Side Way Action Type Jig has two types. One is left compartment side way jig, another is right compartment side way jig. The jig has fixed screen. It is available in separating metallic ores, such as tungsten and gold placer deposits as well as beneficiated tin ore, which not only can be separated fine materials, but coarse also. The largest feed size is 6-8mm but it can be 12mm in few cases.

Application

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Waste recycling machine

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

Package: FCL & LCL export standard container 20GP/40GP/40HQ.

FCL: main machinery gold shaking table in nude package and bulk in container, spare parts in wooden box or as your special requirement

LCL: machinery are packed in steel frame, base and deck are separately packed.

Shipping: by sea shipment, by air shipment or by courier express, it depends on you.

Payment Terms: T/T or L/C is preferable. T/T: 30% deposit and the balance before delivery

We will take photos for your products when finished and show you before delivery. Also keep you informed for any updated information including shipping before you receive it, to let you rest assured.

Delivery time: shipped in 15 days after payment

FAQ

1.How is the quality of your products? (mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice;Finished product pictures will provide to customers before delivery.

Our Service

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed process, and complete process of export

3) After-sales service: Offer considerate technical guidance in installation, debugging and operators training. We are available at any time if you need.

Contact

JiangXi Victor International Mining Equipment Co.,Ltd

Mob: 86-15390744419

Tel/Fax: 86-797-5712751

Add:Guzhang industrial park,Shicheng county,Ganzhou city,Jiangxi Province,342700,China

Rectangle Compartment Side Way Action Type Jig has two types. One is left compartment side way jig, another is right compartment side way jig. The jig has fixed screen. It is available in separating metallic ores, such as tungsten and gold placer deposits as well as beneficiated tin ore, which not only can be separated fine materials, but coarse also. The largest feed size is 6-8mm but it can be 12mm in few cases.

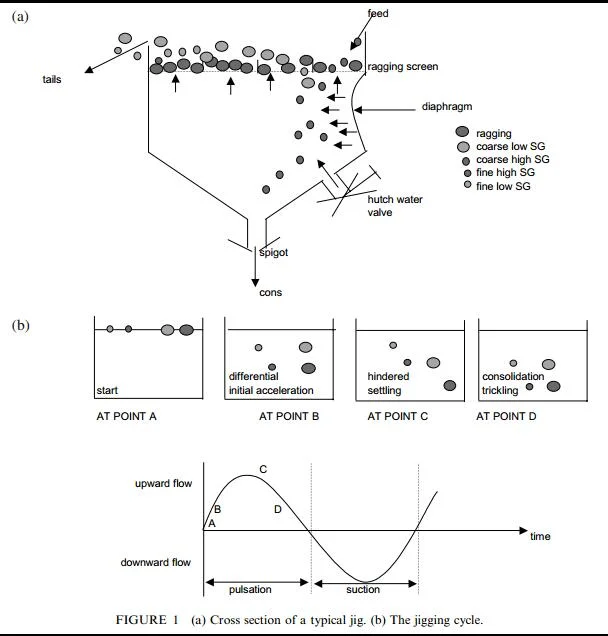

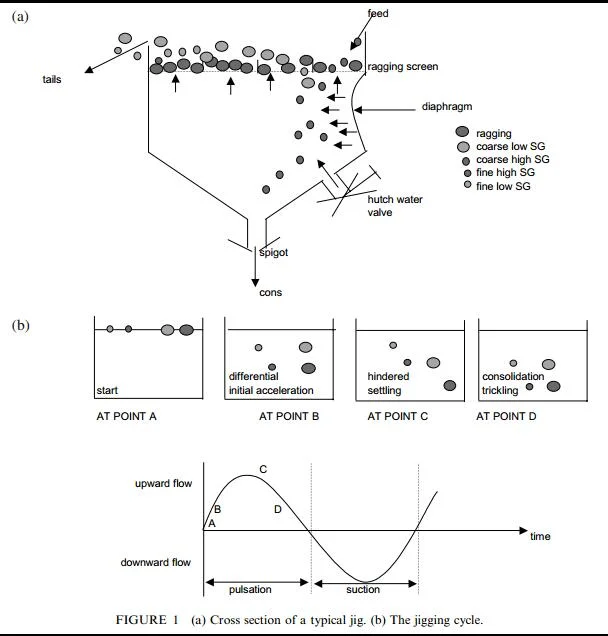

Application

Rectangle Compartment Side Way Action Type Jig is mainly composed of jig box, drive device, water distribution, diaphragm and bibcock. There are two jig buckets with different sizes and each diaphragm is divided into jig area and diaphragm area by clapboard. The rubber diaphragm pumping to make medium (water) moving is the jigging course. The triangle belt drives big belt pulley by electromotor so connecting rod of the eccentric gear and rocker are up and down moving. Another connecting rod is connected with the rubber diaphragm which is moving up and down to jig. Based on the size of ore, we can change the stroke of connecting rod and choose different stroke to make the best jigging effect. The method of altering stroke per minute is to exchange a smaller belt pulley but there are two strokes per minute: 322r/m; 420r/m. The method of choosing stroke is to loose bolt and screw cap, take out bowel and move the relative place between eccentric adjusting sieve and eccentric shaft so there are 11 different strokes (0-25.3mm). Because of a sieve added on the working screen, the jig can be processed the uneven sizes of material. (note: the sieve can be requested to supply or not). After the feed ores are sent to jig chamber, the ores are separated to different layers in the medium by the pulsation of diaphragm. The light but weight is sank to the tank of jig bucket through the spaces of materials of artificial bed layer and its sieve holes but the coarse but light is washed to the discharge end of screen by medium. Because the back jig chamber is lower 50mm than front jig chamber, the light ores is overflowed through front jig chamber to the back chamber and jigged again. If needed, the place of end plate can be adjusted to control the discharge amount. The concentrate in tank can be discharged by discharge tube regularly.

Technical Parameters

| Model | Cham shape | Ber Area m2 | feeding size(mm) | Water added | Water pressure(Mpa) | Capacity | Power(kw) | Dimension (mm) | Weight(kg) |

| JT-0.57 | Ladder | 0.57 | <15 | 5~20 | >0.5 | 1~2 | 1.5 | 1530*780*1550 | 612 |

| JT1-1 | Ladder | 1 | <20 | 8~25 | >0.5 | 2~3 | 2.2 | 2060*1112*1890 | 989 |

| JT2-2 | Rect | 2.28 | <20,screen on top<60 | 35~50 50~65 | >0.5 | 7.5~10 7.5~15 | 3 single motor 2.2*2 dual motor | 2870*1520*1880 | 1637 |

| JT3-1 | Ladder | 3.3 | <20 | 35~50 | >0.5 | 10~15 | 5.5 | 2662*2000*3030 | 3260 |

| JT4-2 | Rect | 4.86 | <20,screen on top<60 | 50~65 65~80 | >0.5 | 15~20 15~30 | 7.5 single motor 5.5*2 dual motor | 4240*1990*2750 | 3500 |

| JT5-2 | Ladder | 5 | <20,screen on top<60 | 50~65 65~80 | >0.5 | 16~23 16~33 | 7.5 single motor 5.5*2 dual motor | 3940*2006*2580 | 3854 |

Detailed Images

Company Information

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team. With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Waste recycling machine

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

Package: FCL & LCL export standard container 20GP/40GP/40HQ.

FCL: main machinery gold shaking table in nude package and bulk in container, spare parts in wooden box or as your special requirement

LCL: machinery are packed in steel frame, base and deck are separately packed.

Shipping: by sea shipment, by air shipment or by courier express, it depends on you.

Payment Terms: T/T or L/C is preferable. T/T: 30% deposit and the balance before delivery

We will take photos for your products when finished and show you before delivery. Also keep you informed for any updated information including shipping before you receive it, to let you rest assured.

Delivery time: shipped in 15 days after payment

FAQ

1.How is the quality of your products? (mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice;Finished product pictures will provide to customers before delivery.

Our Service

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed process, and complete process of export

3) After-sales service: Offer considerate technical guidance in installation, debugging and operators training. We are available at any time if you need.

Contact

JiangXi Victor International Mining Equipment Co.,Ltd

Mob: 86-15390744419

Tel/Fax: 86-797-5712751

Add:Guzhang industrial park,Shicheng county,Ganzhou city,Jiangxi Province,342700,China