- Overview

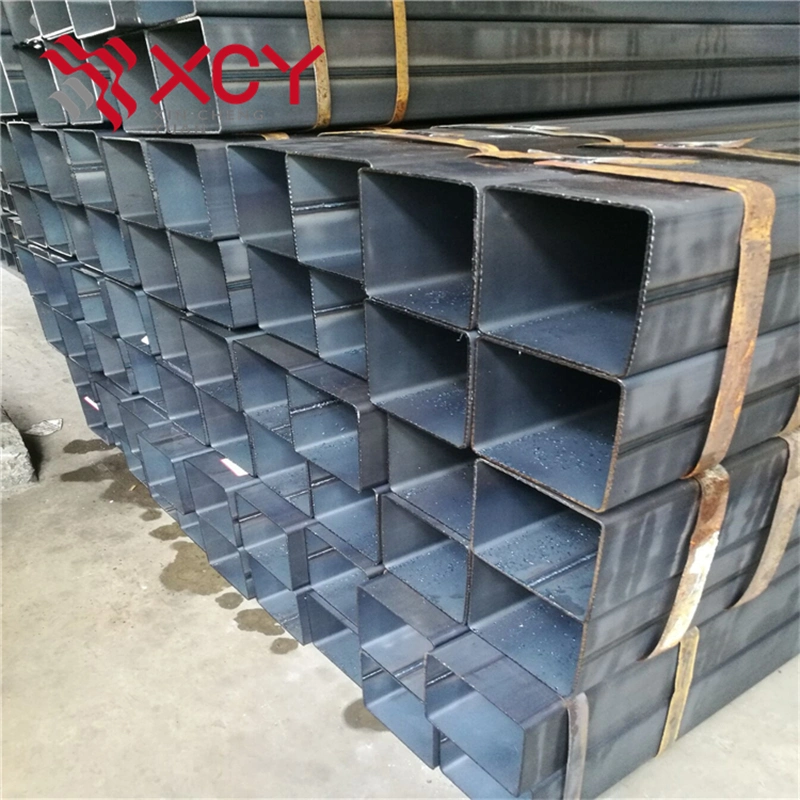

- Product Description

- Application

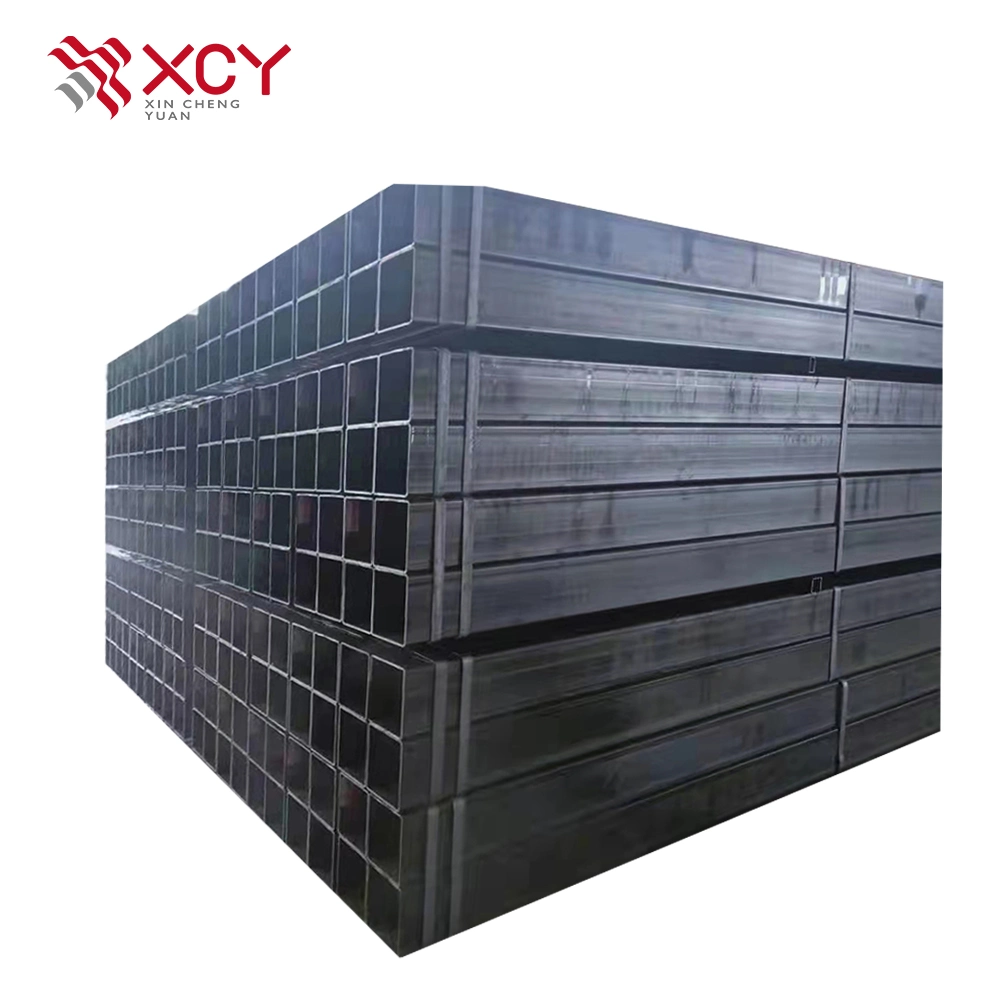

- Packaging & Shipping

- Company Profile

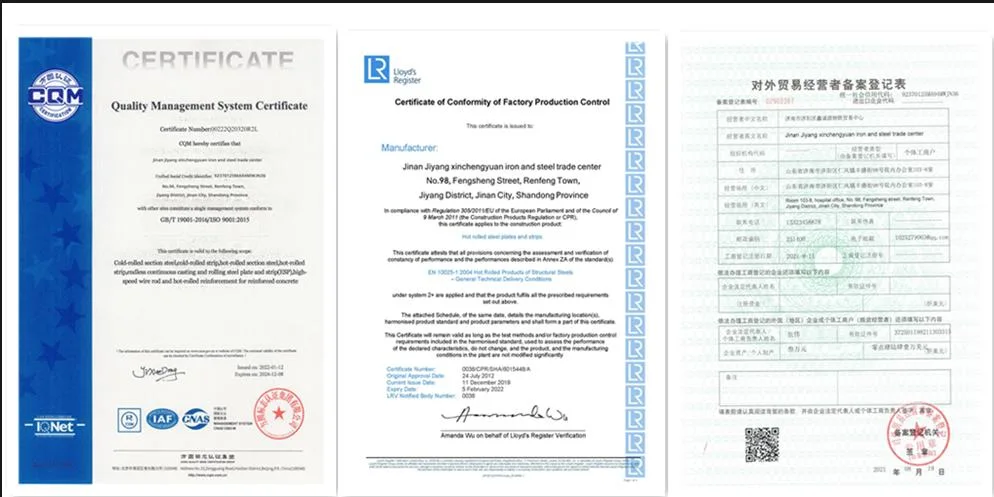

- Certifications

- FAQ

Basic Info.

Product Description

The complex chemical and physical properties of the various grades of carbon steel pipe allow for a broad range of service usage. American Piping Products has the right grade, size and price to meet your requirements, including A/SA-106 GRADE B/C and API 5L X-42 thru X-70. A/SA-106 Grades B & C are utilized for services ranging from structural supports to steam drum headers with temperature ranges up to 800°F, while API 5L X Grades 42 thru 70 are utilized for the water and petroleum industry to transport liquids or as platforms on off-shore rigs.

Carbon steel piping is a durable material made from carbon steel, a steel alloy with iron and carbon. Because of its strength and ability to withstand stress, carbon steel pipe is used in a variety of heavy-duty industries like infrastructure, ships, distillers, and chemical fertilizer equipment.

Benefits of Carbon Steel Piping

Carbon steel piping is a durable material made from carbon steel, a steel alloy with iron and carbon. Because of its strength and ability to withstand stress, carbon steel pipe is used in a variety of heavy-duty industries like infrastructure, ships, distillers, and chemical fertilizer equipment.

Benefits of Carbon Steel Piping

Carbon steel piping provides safety and durability. Because it is shock resistant and not affected by harsh environmental conditions like pressure or extreme weather, it is an ideal material for structural applications.

| product name | carbon steel square pipe |

| material | Q195,Q235,Q345,Q275,A36,A53,A106,A192,ST52,Q355,A210,T12,T11,P5,P9,P91,T22,A333,4140,5135 etc. |

| standard | AISI,ASTM,JIS,GB,DIN,EN,SUS,etc |

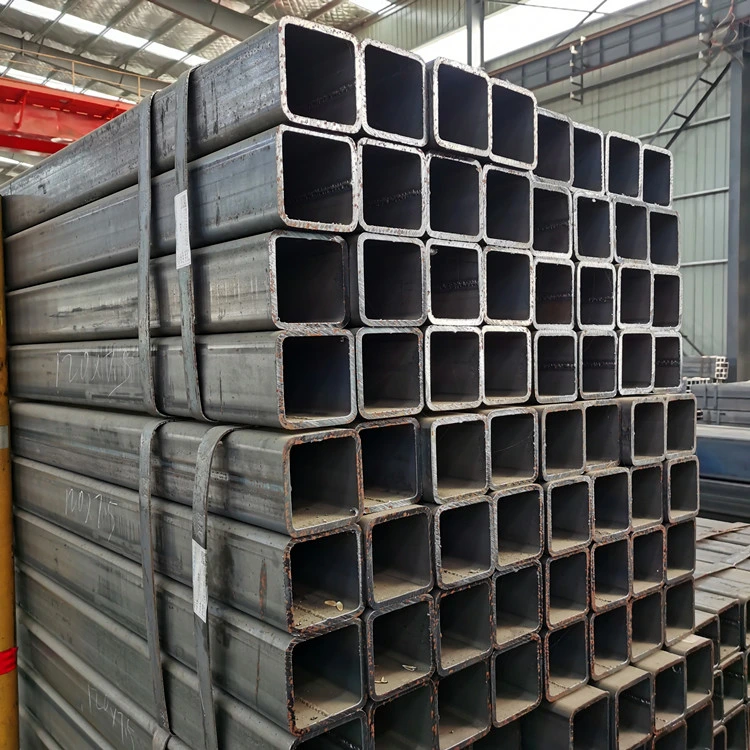

| Size | Rectangular Tube: 10*20-120*80mm Square Tube : 16*16-250*250 mm (check sizes provided from below table) |

| thickness | 0.5-30mm or as request |

| grade | 1.7220,1.7336,1.2601,1.7380,1.7335,1.0033,1.0116 etc. |

| application | Widely used in construction, chemical, food, agriculture, ship parts and other industries. Suitable for train, airplane, conveyer belt, vehicle, bolt, nut, spring, screen, etc. |

| payment terms | 30% TT deposit ,the balance T/T or L/C at sight |

| Price term | Ex-work,FOB,CIF,CFR,etc |

| delivery time | 7-15 days after receving the deposit |

| packing | Export standard package, suit for all kinds of transport, or as required. |

| Shipment | by bulk or load into 20ft / 40ft containers |

Carbon Steel Pipes

The incredible strength of carbon steel means that carbon steel pipe can be made thinner and with less material while still being able to transport high volumes. This makes carbon steel piping a cost-effective material. Not only can less of it be used, but carbon steel is also recyclable, making it both environmentally-friendly and cost-effective.

Because it's easy to manufacture, carbon steel piping is a versatile material. We can make it in a variety of thicknesses and dimensions. It's also easy to cut and bent to fit wherever it's needed. Its also easily connected to joints, valves, and other pipe fittings.

Standard Carbon Steel Pipe Specifications & Grades

| Grade A | Grade B | Grade C | |

| Carbon max. % | 0.25 | 0.30* | 0.35* |

| *Manganese % | 0.27 to 0.93 | *0.29 to 1.06 | *0.29 to 1.06 |

| Phosphorous, max. % | 0.035 | 0.035 | 0.035 |

| Sulfur, max. % | 0.035 | 0.035 | 0.035 |

| Silicon, min.% | 0.10 | 0.10 | 0.10 |

| Chrome, max. % | 0.40 | 0.40 | 0.40 |

| Copper, max. % | 0.40 | 0.40 | 0.40 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 |

| Nickel, max. % | 0.40 | 0.40 | 0.40 |

| Vanadium, max.% | 0.08 | 0.08 | 0.08 |

| *Unless otherwise specified by the purchaser, for each reduction of 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.65% (1.35% for ASME SA106). | |||

A/SA-106

ASTM A106 seamless steel pipe (also known as ASME SA106 pipe) is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers, and ships where the piping must transport fluids and gases that exhibit higher temperatures and pressure levels.

Scope

ASTM A106 Seamless Pressure Pipe (also known as ASME SA106 pipe) covers seamless carbon steel nominal wall pipe for high-temperature service. Suitable for bending, flanging and similar forming operations.

NPS 1-1/2″ and under may be either hot finished or cold drawn. NPS 2″ and larger shall be hot finished unless otherwise specified.

Process

Killed steel, with primary melting process being open-hearth, basic-oxygen, or electric-furnace, possibly combined with separate degassing or refining.

1/2" Nominal to 24"O.D. Seamless Pipe

Wall Thicknesses - Schedule 40 up to 4.000"

| Type E | Type F | ||||

| Type S (seamless) | (electric- resistance welded) | (furnace- welded pipe) | |||

| Grade A | Grade B | Grade A | Grade B | Grade A | |

| Carbon max. % | 0.25 | 0.30* | 0.25 | 0.30* | 0.30 |

| Manganese % | 0.95 | 1.2 | 0.95 | 1.2 | 1.2 |

| Phosphorous, max. % | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Sulfur, max. % | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

| Copper, max.% | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Nickel, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Chromium, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.4 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Vanadium, max. % | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| *For each reduction below 0.01% below the specified carbon maximum, an increase of 0.06% manganese above the specified maximum will be permitted up to a maximum of 1.65% (does not apply to SA53). | |||||

ASTM A53 pipe (also referred to as ASME SA53 pipe) is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas and air lines. It is suitable for welding and for forming operations involving coiling, bending, and flanging, subject to certain qualifications.

American Piping Products stocks a full range of A53 pipe (SA53 Pipe) in:

Grade B

NPS 1/8" to 26" diameter

Schedules 10 through 160, STD, XH and XXH

Scope

ASTM A53 pipe covers Seamless and Welded, Black and Hot-Dipped Galvanized nominal (average) wall pipe for coiling, bending, flanging and other special purposes and is suitable for welding. Continuous-Welded pipe is not intended for flanging. Purpose for which pipe is intended should be stated on order.

Materials and Manufacture

The steel for both seamless and welded pipe shall be made by one or more of the following processes: open-hearth, electric furnace, or basic-oxygen. The weld seam of electric-resistance welded pipe in Grade B shall be heat treated after welding.

High Yield Carbon Steel Pipe Specifications & Grades

API5L Seamless - Grades B (X42, X52, X60, X65 and above)

High Yield Carbon Steel Flanges & Fittings

High Yield Butt Weld Fittings: A- 860 or MSS SP75

WPHY42 (Y52, Y56, Y60, Y65)

High Yield Flanges: A-694 (F42, F52, F56, F60, F-65)

Building foundations

Transporting natural gases or oil

Boiler and condenser tubes

Transporting wastewater

Chemical Processing

High-pressure applications

Transporting sewage

Bollard construction

Shipbuilding

Shoring

Trash enclosures

Distillers

OEM applications

Square pipes are used in construction, machinery manufacturing, steel construction and other projects, shipbuilding, solar power generation support, steel structure engineering, electric power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, boiler construction, highway railings, housing construction, pressure vessels, oil storage tanks, bridges, power station equipment, lifting and transportation machinery and other welded structural parts with high loads. It is widely used.

1. Where is your factory ?

Our company's processing center is located in Shandong, China.

Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on.We can provide a wide range of personalized services according to the customers' needs.

2. What are your company's main products ?

Our main products are stainless steel plate/sheet, coil, round/square pipe, bar, channel, etc.

3. How do you control quality ?

Mill Test Certification is supplied with shipment, Third Party Inspection is available.

4. What are the advantages of your company ?

We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Iran, Turkey, Jordan,India, etc.