- Overview

- Product Parameters

- Product Description

- Storage capacity

- Quality inspection

- Product Usage

- Packaging & Shipping

- Company Profile

- Certifications

Basic Info.

Product Description

| Product Name | Galvanized steel pipe |

| Material | A53 B, St37-2, St52-4, |

| Wall thickness | 1mm~20mm |

| Outer Diameter | 21.3MM~1620MM |

| Physical Property | API 5L, ASTM A53, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M, BS 1387 |

| Grade | A53 B , ST37-ST52 |

| Surface Treatment | 1. Galvanized 2. Black 3. Transparent oil,anti-rust oil |

| Pipe Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

| Certificate | API 5L,FM,UL, CE, |

| Application | Suitable for fire piping system,air,gas,oil and so on |

| | Buyer's drawing or designs are available |

The characteristics of galvanized steel pipes :

The characteristics of galvanized steel pipes :

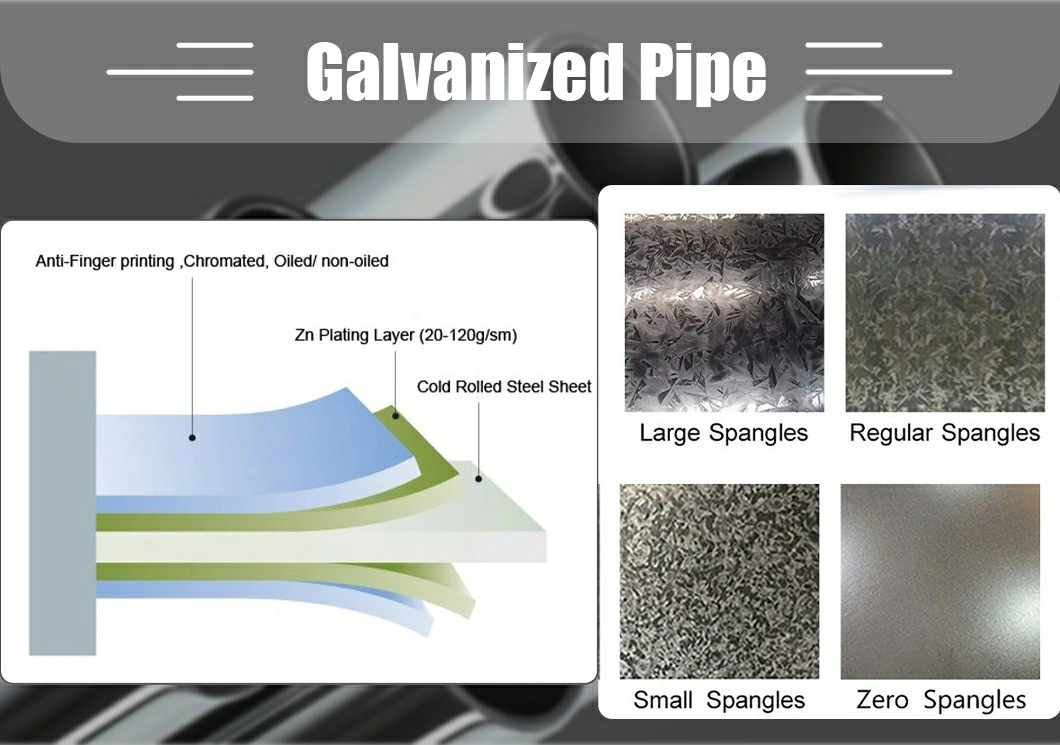

1. The zinc layer on the inner and outer surfaces is thick, with a bright and uniform color, and strong corrosion resistance;

2. Pipe wall thickness, strong mechanical properties, good compression and bending resistance;

3. Small caliber optional threaded thread and sleeve tight set type; Large diameter options include socket expansion and clamp connection.

Galvanized square pipe is a kind of hollow square sectional steel pipe with square section shape and size made of hot rolled or cold rolled galvanized strip steel or galvanized coil as billet by cold bending processing and then by high frequency welding, or the cold formed hollow steel pipe made in advance by hot dip galvanized square pipe processing.

Because the galvanized square pipe is galvanized on the square pipe, the application range of galvanized square pipe has been greatly expanded compared with the square pipe. It is mainly used in curtain wall, construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation bracket, steel structure engineering, power engineering, power plant, agriculture and chemical machinery, glass curtain wall, automobile chassis, airports and so on.

Galvanizing has stronger protective effect and strong corrosion resistance. The entire structure is made of zinc, forming a dense quadruple junction crystal, which forms a barrier on the steel plate and thus effectively prevents the penetration of corrosion factors. Corrosion resistance The barrier layer from zinc provides strong protection. When zinc is sacrificed for protection in the cut edges, scratches and abrasion parts of the coating, zinc forms an insoluble oxide layer, which acts as a barrier protection.

The production process of galvanized pipes:

It can be divided into three basic methods: cold drawing, cold rolling, and hot rolling

Adequate supply of goods in the warehouse

1. The company has stable and good supply channels with sufficient supply sources

2. Complete goods, quality assurance, and delivery speed

3. Support wholesale and retail

We have a strict quality system, the raw materials of each order will be tested before production, and a rolling mill test certificate will be provided to customers.

Galvanized square pipe is a special pipe with hollow cross section, and it is precisely because of this special design that the application of this pipe in our lives has been expanded a lot. Especially in our shipbuilding and construction industries, but also in the military, aviation field has also made great progress. Galvanized square pipe from the production process is divided into hot galvanized square pipe and cold galvanized square pipe. It is precisely because of the different processing methods of these two galvanized square pipes that they have many different physical and chemical properties. We must use correctly and reasonably in order to play the role of galvanized square pipe. In general, there are many differences in strength, toughness and mechanical properties.

Hot-dip galvanized square tube: It is a square tube welded after the use of steel plate or steel strip crimping, and on the basis of this square tube, the square tube is placed in the hot-dip galvanized pool after a series of chemical reactions. The production process of hot-dip galvanized square pipe is relatively simple, and the production efficiency is very high, the varieties and specifications are also many, and the equipment and funds required for this kind of square pipe are very little, which is suitable for the production of small galvanized square pipe manufacturers. However, in terms of strength, the strength of this steel pipe is far lower than that of seamless square pipe.

The cold galvanized square pipe is to use the principle of cold galvanized on the square pipe used to make the square pipe have anti-corrosion performance. Different from hot-dip galvanized coating, cold galvanized coating is mainly anti-corrosion through the electrochemical principle, so it is necessary to ensure that the zinc powder is in full contact with the steel, resulting in electrode potential difference, so the surface treatment of steel is very important.

galvanized steel pipe/tule It is widely used in subway, tunnel and other underground structure, along the river, coastal areas, and high standard civil, commercial, and public buildings for the installation of exposed and concealed electrical lines, pipelines, and civil air defense projects.

Galvanized square pipe has two categories: hot-dip galvanized square pipe and electric galvanized square pipe. Hot-dip galvanized square pipe has wet method, dry method, lead-zinc method, REDOX method and so on. The main difference between different hot dip galvanizing methods is what method is used to activate the surface of the pipe to improve the quality of galvanizing after the acid dip cleaning of the steel pipe. At present, dry method and REDOX method are mainly used in production, and their characteristics are shown in the table. The surface of the zinc layer of electrogalvanizing is very smooth and compact with uniform structure. Good mechanical properties and corrosion resistance; The zinc consumption is 60% ~ 75% lower than that of hot dip galvanizing. Electrogalvanizing has a certain complexity in technology, but this method must be used for single-sided coating, double-sided coating with different thickness of internal and external surface coating, and thin-wall pipe galvanizing.

1.Every cartons loaded with good shoring and strengthening in container well to make it safe arrive at destination port.

2.Take container loading pictures and seal the container.

3.Transportation speed is quick. And keep customer eachstep informed.

Shandong Zhongtuo New Material Group Co.,Ltd. is located in Jinan, Shandong Province.It is one of stainless steel bases in China.

Shandong Zhongtuo New Material Group Co.,Ltd. is located in Jinan, Shandong Province.It is one of stainless steel bases in China.

Our main products including stainless steel pipe ,stainless steel plate , stainless steel bar , stainless steel coil , stainless steel round bar , Stainless steel square tube ,stainless i-beam , stainless angle steel , stainless steel channel , Hastelloy alloy,Superalloy , Nickel molybdenum alloy,Inconel alloy,Monel alloy,Soft magnetic alloy,etc .Our company has the most advanced production equipment which guarantee the most advantageous product quality . Based on highly quality products and best service , we have develop clients all round the world ,our products are widely used in industry in USA ,Germany ,India ,Iran , Dubai , Iraq , Vietnam , Ireland , Singapore ,and so on .The specifications are complete and the price is favorable.Our company can order various non-standard specifications on behalf of customers.special material steel products, can be delivered to your door, ordering quickly.

Our company can provide customers with carbon steel, aluminum zinc plating, stainless steel pipes, alloy steel products,round steel and non-standard thermal expansion stainless steel pipes of different specifications and materials. All steel products operated by our company comply with national standards, and a list of raw materials of the steel plant is attached. At the same time, it can also handle steel ordering business of various specifications and materials and railway and highway transportation business for the majority of users. Main materials: Q235, Q345, Q235B, Q195L, dx51d, dx52d, SPCC, 301304304l, 304n, 304lm, xm21305309s, 3105316316l, 316N, 316LN, 317317l, 340,430,403,410,420 440a, 2205.2207, etc.

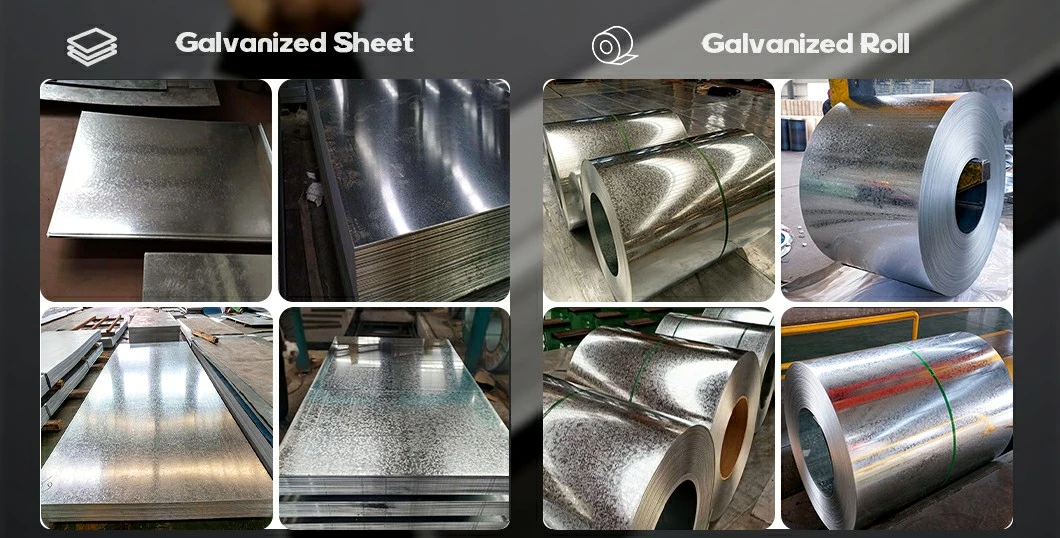

Shandong Zhongtuo New Material Group Co., Ltd. is a large steel enterprise group with an annual steel export volume exceeding 15 million tons. Located in Shandong Province, with convenient transportation and air transportation, it is adjacent to Tianjin Port to the north, Qingdao Port to the east, and Shanghai Port to the south. The main products include stainless steel plates/coils/pipes, carbon steel plates/coils/pipes, and galvanized steel coils. There are also sets of structural steel and accessories such as galvanized sheet, tinplate, round steel, threaded steel, roof panel, spring steel strip, PPGI, PPGL, etc.

Shandong Zhongtuo New Material Group Co., Ltd. is a large steel enterprise group with an annual steel export volume exceeding 15 million tons. Located in Shandong Province, with convenient transportation and air transportation, it is adjacent to Tianjin Port to the north, Qingdao Port to the east, and Shanghai Port to the south. The main products include stainless steel plates/coils/pipes, carbon steel plates/coils/pipes, and galvanized steel coils. There are also sets of structural steel and accessories such as galvanized sheet, tinplate, round steel, threaded steel, roof panel, spring steel strip, PPGI, PPGL, etc. Customer Visits

Customer Visits

We warmly welcome .In order to make a good reception service , Before coming to china , Pls kindly inform us your arrival schedule in advance

Including arrive the date and name of airport or railway station ,

1)How many people will be coming ,

2)How long will you stay in china

3)How about your business and travel schedule in china

We will have special people to pick up you when you arrive in china ,also will be accompanied with you to visit our factory . Meanwhile ,if the time is allowed , we will also show you around some famous place in china ,also you can inform us what place you are interest in visiting , we can give you some travel planning after finishing visiting our factory .We will provide necessary accommodation catering service , For sure , If you have any taboo ,pls let us know in advance .

We will try our best to supply high-quality service , We sincerely hope after this trip , not only achieve mutually beneficial cooperation ,but also you will have a good trip in china.

Over the years, Shandong Zhongtuo New Material Group Co., Ltd. has established long-term friendly cooperative relationships with many customers around the world. Every year, many famous buyers come to our factory for inspection, and our products have been recognized by them.

Over the years, Shandong Zhongtuo New Material Group Co., Ltd. has established long-term friendly cooperative relationships with many customers around the world. Every year, many famous buyers come to our factory for inspection, and our products have been recognized by them.

FAQ

Q1:Where is your factory?

A:Our company's processing center is located in Shandong China.

Q2:What is your delivery time?

A:For products in stock, we can ship it within 7 days after receiving the deposit. For customer order, production time is 15-30 workdays after receiving the deposit.

Q3:Can I place an sample order and what is your MOQ if I accept your quality?

A:Yes, we can send you samples but you may pay the express fees and customized samples will take about 5-7days, our MOQ is 1 ton.

Q4:How could you guarantee your products?

A:Mill Test Certification is supplied with shipment, We also accept and support the third-party inspection.We also could issue the warranty to customer to guarantee the quality.

Q5:How can I get the price of needed product?

A:It's the best way if you can send us the material, size and surface, so we can produce for you to check the quality.If you still have any confusion, just contact us, we would like to be helpful.

Q6: Why do you want to buy from us instead of from other suppliers?

A:Our own factory, dealing in steel materials, such as steel plate, steel pipe, steel rod, steel wire, tinplate, aluminum products. Welcome to our company product exhibition, looking forward to our perfect cooperation.