Basic Info.

Model NO.

XGQT01

Shape

Equal

Head Code

Round

Angle

90 Degree

Wall Thickness

Sch10

Material

Iron

Technics

Casting

Certification

FM, UL, CE

Color

Red

Coating

Epoxy, Painted, Galv. Dacromet

Pressure

300psi

Delivery Time

15-30 Days

OEM

Available

Transport Package

Cartons with Plywood Pallets, Crate

Specification

1"-12"

Trademark

SDSX

Origin

China

HS Code

73071100

Production Capacity

100000 Tons

Packaging & Delivery

Package Size

34.50cm * 34.50cm * 15.00cm

Package Gross Weight

15.000kg

Product Description

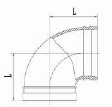

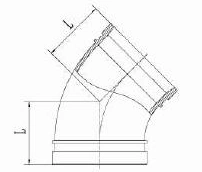

SDSX Grooved Fittings-90° Elbow

Description

SDSX offers different kinds of elbows, tees, caps

crosses and reducers manufacturered from ductile iron

in accordance with ASTM A-536, grade 65-45-12.

They are available in sizes 25mm (1") through 350mm (14")

They are available in sizes 25mm (1") through 350mm (14")

Dimensions

Material Specification

Housing: Ductile iron conforming to ASTM A-536, grade 65-45-12.

Size | Pipe O.D. | 90°Elbow | 45°Elbow | 22.5°Elbow | 11.25°Elbow | |

| Standard | Short | |||||

| L | L | L | L | L | ||

| DN | mm | mm | mm | mm | mm | mm |

| In. | In. | In. | In. | In. | In. | In. |

|  |  |  | |||

| 25 | 33.7 | 57 | 57 | 38 | 41 | 35 |

| 1 | 1.315 | 2.24 | 2.244 | 1.496 | 1.61 | 1.377 |

| 32 | 42.4 | 70 | 60 | 44 | 44 | 35 |

| 1¼ | 1.660 | 2.755 | 2.362 | 1.732 | 1.732 | 1.377 |

| 40 | 48.3 | 70 | 60 | 44 | 44 | 35 |

| 1½ | 1.900 | 2.755 | 2.362 | 1.732 | 1.732 | 1.377 |

| 50 | 57.0 | 83 | 70 | 51 | 51 | 35 |

| 2 | 2.244 | 3.267 | 2.755 | 2.007 | 2 | 1.377 |

| 50 | 60.3 | 83 | 70 | 51 | 51 | 35 |

| 2 | 2.375 | 3.267 | 2.755 | 2.007 | 2 | 1.377 |

| 65 | 73.0 | 95 | 76 | 57 | 51 | 38 |

| 2½ | 2.875 | 3.74 | 2.992 | 2.007 | 2 | 1.496 |

| 65 | 76.1 | 95 | 76 | 57 | 51 | 38 |

| 2½ | 3.000 | 3.74 | 2.992 | 2.007 | 2 | 1.496 |

| 80 | 88.9 | 108 | 86 | 64 | 57 | 38 |

| 3 | 3.500 | 4.251 | 3.386 | 2.519 | 2.244 | 1.496 |

| 100 | 108.0 | 127 | 101.5 | 76 | 73 | 44 |

| 4 | 4.252 | 5 | 3.996 | 2.992 | 2.874 | 1.732 |

| 100 | 114.3 | 127 | 101.5 | 76 | 73 | 48 |

| 4 | 4.500 | 5 | 3.996 | 2.992 | 2.874 | 1.889 |

| 125 | 133.0 | 140 | 122 | 83 | 73 | 51 |

| 5 | 5.250 | 5.511 | 4.803 | 3.267 | 2.874 | 2.007 |

| 125 | 139.7 | 140 | 122 | 83 | 73 | 51 |

| 5 | 5.500 | 5.511 | 4.803 | 3.267 | 2.874 | 2.007 |

| 150 | 159.0 | 165 | 140 | 89 | 79 | 51 |

| 6 | 6.260 | 6.496 | 5.511 | 3.503 | 3.11 | 2.007 |

| 150 | 165.1 | 165 | 140 | 89 | 79 | 51 |

| 6 | 6.500 | 6.496 | 5.511 | 3.503 | 3.11 | 2.007 |

| 150 | 168.3 | 165 | 140 | 89 | 79 | 51 |

| 6 | 6.625 | 6.496 | 5.511 | 3.503 | 3.11 | 2.007 |

| 200 | 219.1 | 197 | 175 | 108 | 98 | 51 |

| 8 | 8.625 | 7.755 | 6.889 | 4.251 | 3.858 | 2.007 |

| 250 | 273.0 | 229 | 215 | 121 | 111 | 54 |

| 10 | 10.750 | 9.015 | 8.464 | 4.763 | 4.37 | 2.125 |

| 300 | 323.9 | 254 | 245 | 133 | 124 | 57 |

| 12 | 12.750 | 10 | 9.645 | 5.236 | 4.88 | 2.244 |

| 350 | 377.0 | 280 | 280 | 146 | 127 | 89 |

| 14 | 14.843 | 11.024 | 11.024 | 5.748 | 5 | 3.503 |

Material Specification

Housing: Ductile iron conforming to ASTM A-536, grade 65-45-12.

Housing Coating: Paint red and orange

• Optional: Hot dipped galvanized, electro galvanized.

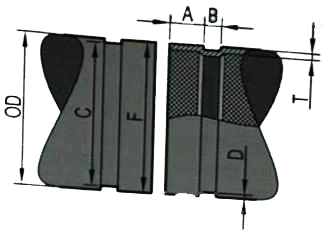

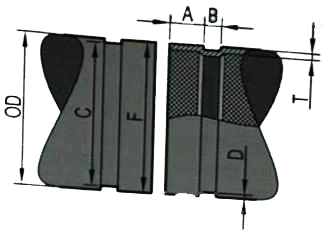

Standard Roll Groove Specifications-Steel and other IPS pipe

Certification

Showroom

Application

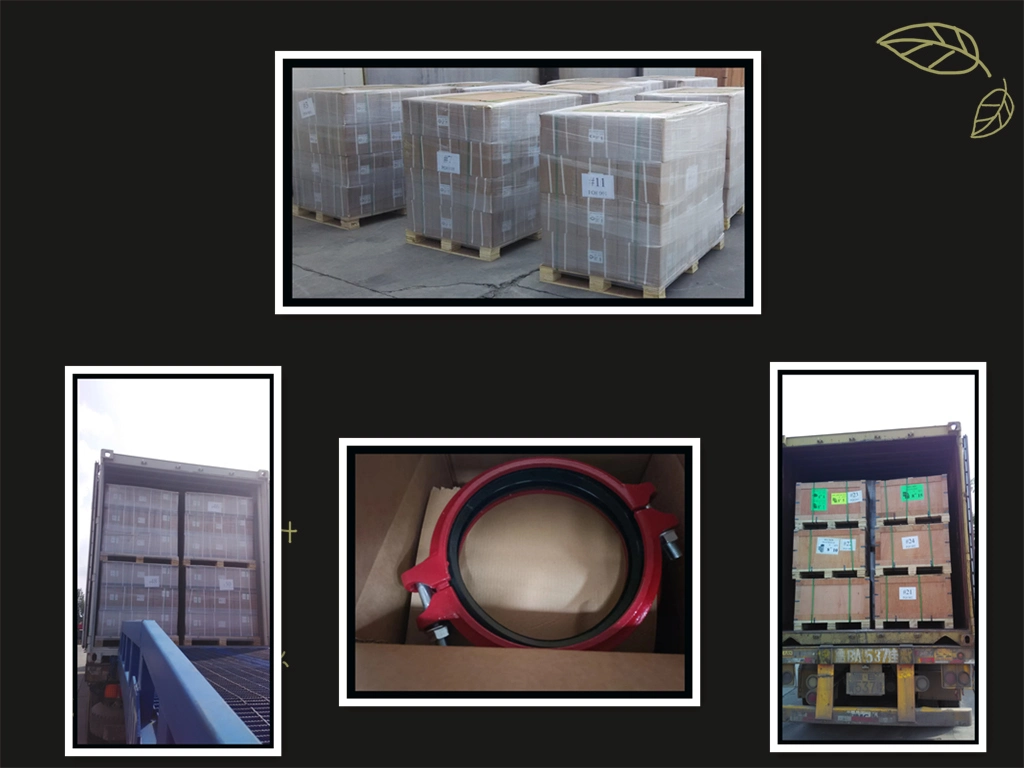

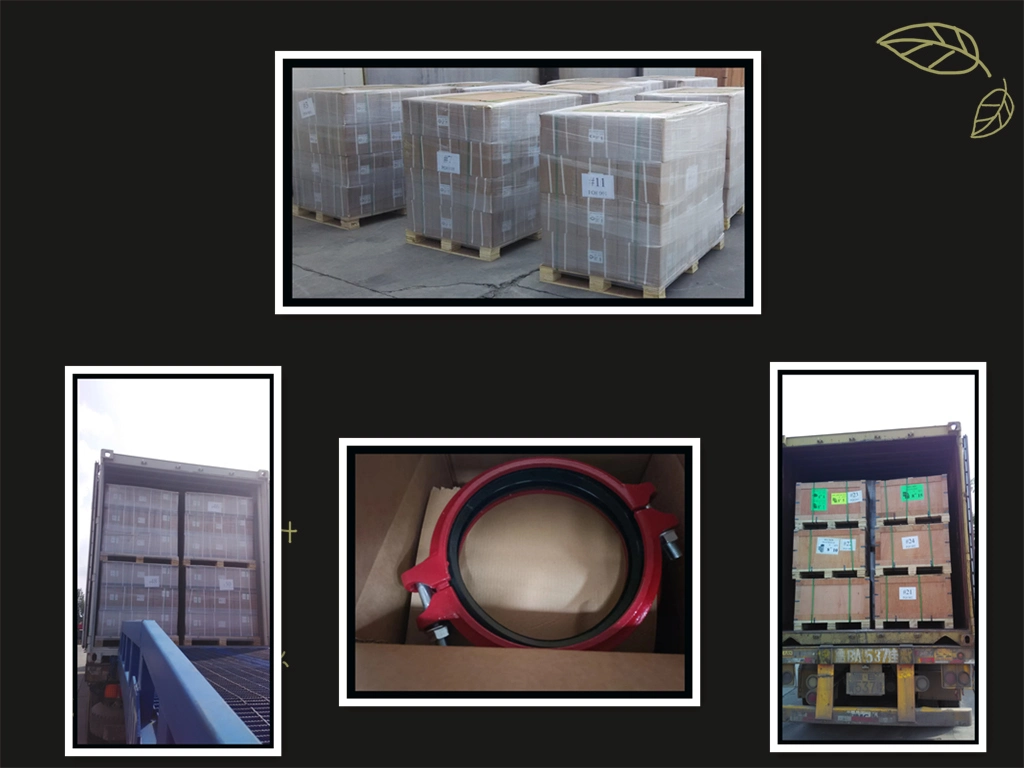

Package and shipment

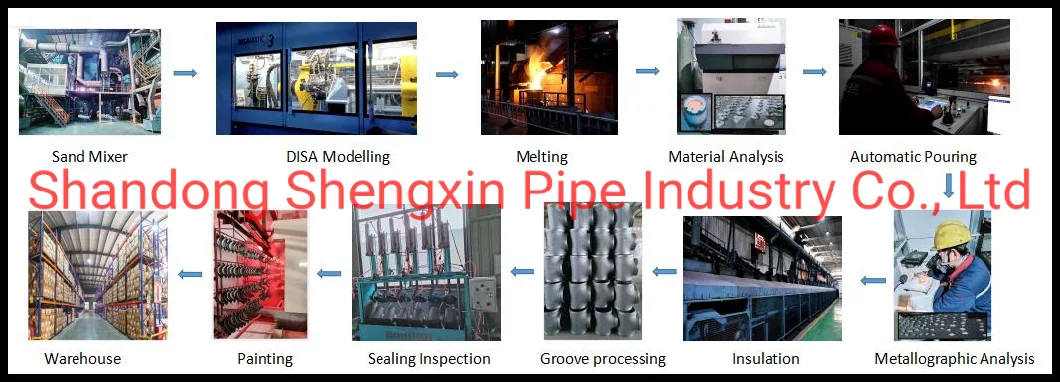

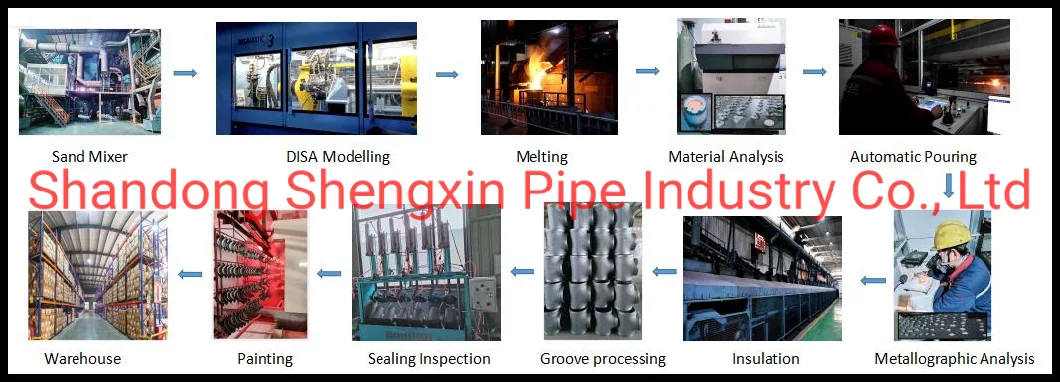

Production and quality control

Standard Roll Groove Specifications-Steel and other IPS pipe

| Size | Gasket Seat | Grv.Width | Grv.Diameter C | Grv.Depth | Min.Wall | Max.Flare | ||||

| Nominal Dia. | Actual O.D. | Tolerance | A | B | Std. | Tolerance | D(Ref) | T | F | |

| DN Inches | mm Inches | mm Inches | mm Inches | ±0.76mm ±0.03In. | ±0.76mm +0.03In | mm Inches | mm Inches | mm Inches | mm Inches | mm Inches |

| 20 3/4 | 26.9 1.050 | 0.25 0.01 | 0.25 0.01 | 15.88 0.625 | 7.14 0.281 | 23.83 0.938 | -0.38 -0.015 | 1.42 0.056 | 1.65 0.065 | 29.2 1.15 |

| 25 1 | 33.4 1.315 | 0.33 0.013 | 0.33 0.013 | 15.88 0.625 | 7.14 0.281 | 30.23 1.19 | -0.38 -0.015 | 1.6 0.063 | 1.65 0.065 | 36.3 1.43 |

| 32 1 1/4 | 42.4 1.660 | 0.041 0.016 | 0.041 0.016 | 15.88 0.625 | 7.14 0.281 | 38.99 1.535 | -0.38 -0.015 | 1.6 0.063 | 1.65 0.065 | 45 1.77 |

| 40 1 1/2 | 48.3 1.900 | 0.048 0.019 | 0.048 0.019 | 15.88 0.625 | 7.14 0.28 | 45.09 1.775 | -0.38 -0.015 | 1.6 0.063 | 1.65 0.065 | 51.1 2.01 |

| 50 2 | 57.0 2.250 | 0.57 0.022 | 0.57 0.022 | 15.88 0.625 | 8.74 0.344 | 53.85 2.12 | -0.38 -0.015 | 1.6 0.063 | 1.65 0.065 | 59.7 2.35 |

| 50 2 | 60.3 2.375 | 0.61 0.024 | 0.61 0.024 | 15.88 0.625 | 8.74 0.344 | 57.15 2.25 | -0.38 -0.015 | 1.6 0.063 | 1.65 0.065 | 63 2.48 |

| 65 2 1/2 | 73.0 2.875 | 0.74 0.029 | 0.74 0.029 | 15.88 0.625 | 8.74 0.344 | 69.09 2.72 | -0.46 -0.018 | 1.98 0.078 | 2.11 0.083 | 75.7 2.98 |

| 65 2 1/2 | 76.1 3.000 | 0.76 0.03 | 0.76 0.03 | 15.88 0.625 | 8.74 0.344 | 72.26 2.845 | -0.46 -0.018 | 1.98 0.078 | 2.11 0.083 | 78.7 3.1 |

| 80 3 | 88.9 3.500 | 0.89 0.089 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 84.94 3.344 | -0.46 -0.018 | 1.98 0.078 | 2.11 0.083 | 91.4 3.6 |

| 90 3 1/2 | 101.6 4.000 | 1.02 0.04 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 97.38 3.834 | -0.51 -0.02 | 2.11 0.083 | 2.11 0.083 | 104.1 4.1 |

| 100 4 | 108.0 4.250 | 1.07 0.042 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 103.73 4.084 | -0.51 -0.02 | 2.11 0.083 | 2.11 0.083 | 110.5 4.35 |

| 100 4 | 114.3 4.500 | 1.14 0.045 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 110.08 4.334 | -0.51 -0.02 | 2.11 0.083 | 2.11 0.083 | 116.8 4.6 |

| 120 4 1/2 | 127 5.000 | 1.27 0.05 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 122.78 4.834 | -0.51 -0.02 | 2.11 0.083 | 2.41 0.095 | 129.5 5.098 |

| 125 5 | 133.0 5.250 | 1.32 0.052 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 129.13 5.084 | -0.51 -0.02 | 2.11 0.083 | 2.77 0.109 | 135.9 5.35 |

| 125 5 | 139.7 5.500 | 1.42 0.056 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 135.48 5.334 | -0.51 -0.02 | 2.11 0.083 | 2.77 0.109 | 142.2 5.6 |

| 125 5 | 141.3 5.563 | 1.42 0.056 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 137.03 5.395 | -0.56 -0.022 | 2.13 0.084 | 2.77 0.109 | 143.8 5.66 |

| 6 6OD | 152.4 6.000 | 1.42 0.056 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 148.08 5.83 | -0.56 -0.022 | 2.16 0.085 | 2.77 0.109 | 154.9 6.1 |

| 150 6 | 159.0 6.250 | 1.6 0.063 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 154.5 6.082 | -0.56 -0.022 | 2.16 0.085 | 2.77 0.109 | 161.3 6.35 |

| 150 6 | 165.1 6.500 | 1.6 0.063 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 160.9 6.334 | -0.56 -0.022 | 2.16 0.085 | 2.77 0.109 | 167.6 6.6 |

| 150 6 | 168.3 6.625 | 1.6 0.063 | 0.79 0.031 | 15.88 0.625 | 8.74 0.344 | 163.96 6.455 | -0.56 -0.022 | 2.16 0.085 | 2.77 0.109 | 170.9 6.73 |

| 200 8 | 216.3 8.500 | 1.6 0.063 | 0.79 0.031 | 19.05 0.75 | 11.91 0.469 | 211.61 8.331 | -0.64 -0.025 | 2.34 0.092 | 2.77 0.109 | 220.7 8.69 |

| 200 8 | 219.1 8.625 | 1.6 0.063 | 0.79 0.031 | 19.05 0.75 | 11.91 0.469 | 214.4 8.441 | -0.64 -0.025 | 2.34 0.092 | 2.77 0.109 | 223.5 8.8 |

| 250 10 | 267.4 10.500 | 1.6 0.063 | 0.79 0.031 | 19.05 0.75 | 11.91 0.469 | 262.6 10.339 | -0.69 -0.027 | 2.39 0.094 | 3.4 0.134 | 271.8 10.7 |

| 250 10 | 273.0 10.750 | 1.6 0.063 | 0.79 0.031 | 19.05 0.75 | 11.91 0.469 | 268.28 10.562 | -0.69 -0.027 | 2.39 0.094 | 3.4 0.134 | 277.4 10.92 |

| 300 12 | 318.4 12.500 | 1.6 0.063 | 0.79 0.031 | 19.05 0.75 | 11.91 0.469 | 312.9 12.319 | -0.76 -0.03 | 2.77 0.109 | 3.96 0.156 | 322.8 12.71 |

| 300 12 | 323.9 12.750 | 1.6 0.063 | 0.79 0.031 | 19.05 0.75 | 11.91 0.469 | 318.29 12.531 | -0.76 -0.03 | 2.77 0.109 | 3.96 0.156 | 328.2 12.92 |

| ·Pipe standard OD and tolerance OD:Confirmed before rolling the groove pipe ,if not, then the pipe is not suitable for rolling groove; ·Sealing surface A:confirm the sealing surface size in line with the requirements of the above table, if it is too large, it will affect the joint installation, too small will affect | ||||||||||

Showroom

Application

Package and shipment

Production and quality control