Basic Info.

Product Description

CHAENG lime rotary kiln to improve production 30%, 40% lower heat consumption, exhaust gas temperature <250 ºC, easy to dust collection, can fully meet energy saving requirements.

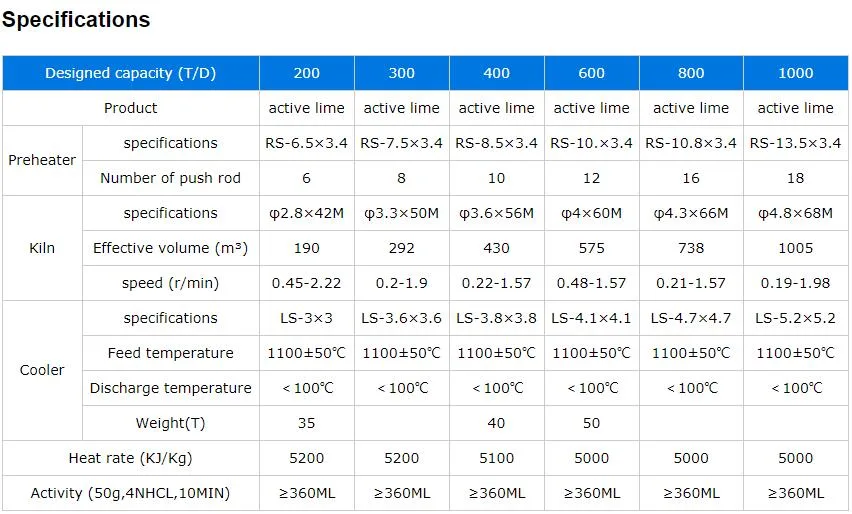

Kiln pitch :3.5-4%

Cylinder diameter :φ1.8-φ4.8 m

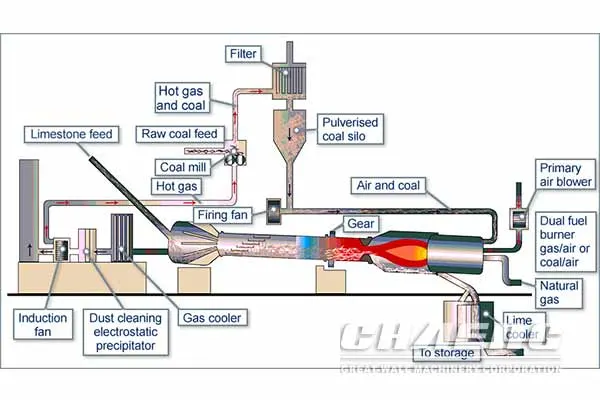

Material will be feed into kiln tail through chute in gas chamber. As kiln shell is inclined and it rotates slightly, material will move along round shell and will also move along shaft direction from kiln tail to kiln head. Material will be processed through pre-heat, decompose, calcined and will be feed into cooler. Fuel will be given through gas or coal burner at kiln head and will be combusted in kiln. Heat will be transferred to material by fire radiate, hot air flow, kiln brick transfer. The heat will heat and calcine material enough and make it final product.

Lime rotary kiln Features

1. Simple operation, large output

Lime rotary kiln can easily and flexibly adjust the yield and quality. Its operation is smooth and the failure rate is low, can improve the work efficiency and production.it can be used in 50-1500TPD active lime production line.

2.Calcined raw material diameter <10mm

CHAENG lime rotary kilns can calcine the limestone raw materials below 10mm to improve the utilization of mining resources, and adopts advanced vertical preheater to effectively improve the preheating effect, making the lime activity ≥ 300 (ml).

3.Energy saving and environmental protection

Projects

In 2014, A company in Guangxi Province, China purchased a φ4.0 × 60m lime rotary kiln from CHAENG, the rotary kiln was installed in 2017, and it was put into use in June 2017.

After use, customers made positive comments that machines of CHAENG have outstanding performance and are good at energy-saving to save large cost for users.

Invest

Lime rotary kiln structure is advanced and simple. The vertical preheater can effectively improve the preheating effect, the preheated limestone enters into the rotary kiln and is calcined at the best calcination temperature of 900 ~ 1100 ºC, the decomposition rate is up to 20 - 25%, more efficiently; the sealing system at both ends of the rotary kiln can make the air leakage coefficient less than 10%, to effectively reduce the loss of heat; the cooler located in the rotary kiln discharge port, can control the lime temperature at 800 ºC, making transport and storage more convenient.

About CHAENG

Founded in 1958 and located in Xinxiang, Henan province, CHAENG with 60-year experience in equipment manufacturing covers an area of 330,000 m2 and its annual production value is 1 billion yuan. The company specializes in manufacturing tube mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel,Voestalpine and ASGT.

Contact us