Basic Info.

Product Description

1. Company Profile

2. Company Information Building site: Chile, South America

Building site: Chile, South America

Building type: 2-storeys metal building steel structure workshop

Structural steelwork used: 2910 tons

Steel building contractor: Chile Construction CO Inc

Steel building subcontractor: Qingdao Jingdao(JDCC) steel

Construction detailling software: XSTEEL

Welding technology: Conformity with AWS certificate

Seam: 100% full penetration welding seam

Surface treatment: Primary member painted Jotun brand epoxy zinc rich primer, secondary member, purlines and addtional fittings, accessories galvanized.

3.Corporate Elegant Demeanor --"Talks with the President of Tanzania"

Qingdao Jingdao Credit Construction Steel Structure Co., Ltd. (JDCC) offers a complete steel construction solution ranging from detailing to on-site erection along with maintenance and after sales services, all under one roof, with over 20 years of experience in steel building manufacturing and design.

Metal frame workshop is the type of building formed by main framework which mainly consists of steel column, steel beam and purlin, thus the steel structure accounts for the major load-bearing member of steel workshop building. The roof and wall of steel workshop utilize various styles of panels that will overlap when assembled together, leaving no openings. As a result, the steel frame workshop can be isolated against outdoor environments. Due to reasonable cost and short construction period, steel structure has been applied in a wide range of industrial and non-industrial building construction.

Metal Workshop features:

We offer frames custom built to your needs, using square steel tubing known for its strength and durability

Insulation available to protect your custom metal workshop for many years to come, keeping your projects safe from harsh temperatures

Customer service representatives will help you find the right custom metal workshop for your needs, whether you need a storage solution or a safe space to complete your projects

Customization options in Workshop Structure:

Custom roof style, custom color, and custom window options are available

We offer custom door solutions, including roll-up and electric garage doors for those larger projects. Electric garage door availability varies by installation location

Custom colors are available for the roof, side panel, and garage doors

JDCC workshop buildings are pre-cut, pre-drilled, and ready for quick and efficient assembly. Maybe you are looking to build an auto repair shop, or just need some extra room for storage; no matter your needs, you can trust Allied to provide durable and ready-to-assemble building kits. These kits are perfectly suited for auto repair shop buildings, residential garages, or a backyard shed. With large bay spacing, mezzanine options, bolted connections, multiple finishes and door systems, our prefabricated steel workshops are designed to suit all of your needs. Every project we engineer is unique to each customer.

4. Projects Show

5. Detailed Description 5. Specifications

5. Specifications

1) Size: MOQ is 100m2, width X length X eave height, roof slope

2) Type: Single slope, double slope, muti slope; Single span, double-span, Multi-span, single floor, double floors!

3) Base: Cement and steel foundation bolts

4) Column and beam: Material Q345(S355JR)(S235JR) steel, all bolts connection! Straight cross-section or Variable Cross-section!

5) Bracing: X or V or other type bracing made from angle, round pipe, etc

6) C or z purlin: Size from C120~C320, Z100~Z200

7) Roof and wall panel: Single colorfull corrugated steel sheet 0.326~0.8mm thick, YX28-205-820(820mm wide), sandwich panel with EPS, ROCK WOOL, PU etc insulation thickness around 50mm~150mm, width 950mm or 960mm!

8) Surfrace: Paint or hot DIP galvanize!

9) Accessories: Semi-transparent skylight belts, Ventilators, down pipe, outer gutter, etc.

10) Packing: Main steel frame without packing load in 40'OT, roof and wall panel load in 40'HQ

(1) Features

Primary Framing Elements-columns, beams and all primary members are made by H section steels- hot rolled section steel/ welded section steel, which will be bolted together at the site. A factory primer and facing paintings are applied to get the better anti-rusting effect of primary framing elements.

Secondary Framing-Purlin, Tie Bar, Roof, and Wall Support are formed as secondary framing

A. Bracing

Round steel is supplied with knee bracing and other supporting parts that need portal framing, which will improve the stability and durability of the whole structural building.

B. Cladding

Roof and Wall are covering of color-coated corrugated steel sheet or steel sandwich panel, hot dipped with zinc and aluminum compound, that is fixed to the outside of the structural building to protect it against bad weather or to make it look more attractive and last for generations.

C. Windows and Doors

Windows: Plastic Steel Window/Aluminum-alloy Window

Door: Sliding Door/Rolling Door

D. Other Options

Gutter, Downpipe, Transparent sheet, Ventilator, and Bridge Crane will be fitted according to the client's requirements

(2) Application

Warehouse, temporary office/building, gymnasium, villa, mobile building, guard booth, wall & roof materials for steel building or structure.

6. Packaging & Shipping

7. Company Information

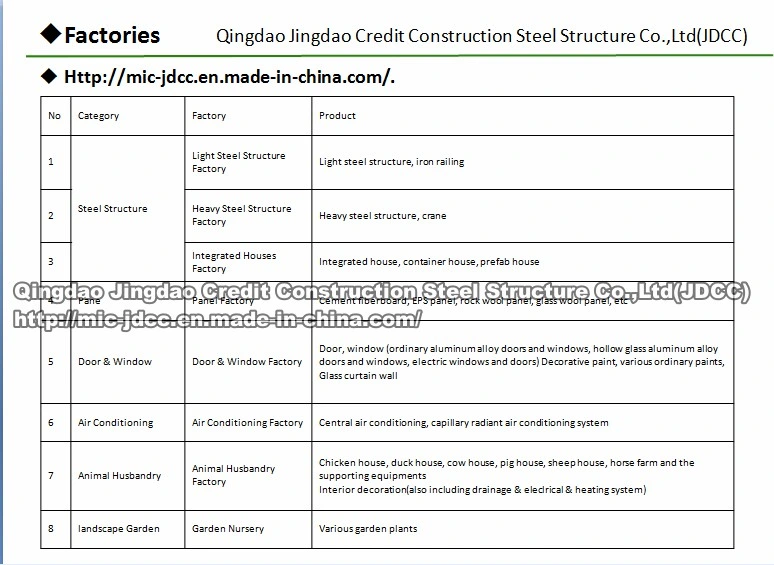

Qingdao Jingdao Credit Construction Steel Structure Co.,Ltd(JDCC) is the group member unit of China Steel Structure Association; The member of China Construction Metal Structure Association; Committee unit of China Chamber of International Commerce and is rated as Credit enterprise (class AAA) by Ministry of Commerce and SASAC of PRC. It has also been listed into the Modern Production Base of Construction Industry in Shandong Province and has achieved the honor of famous mark of Shandong Province.

Due to its powerful technique and rich engineering experience, we have achieved National Professional Contractors for steel structure projects (class A); Anti-water, anti-rust and thermal insulation; Architectural decoration; Professional Contractors for architectural curtain wall (Class B), EN1090 Certification (CE); Global normal steel structure advanced certificate (EXC-3). We have now become a high-tech, diversified and export-oriented international private enterprise integrating R&D, design, production, installation construction, and service. We have joined in many constructional projects: Haier, Hisense, Sinopec, airport, subway; And has cooperated with large enterprises like CSCEC and Powerchina.

6. Market

Partial List of Steel Structure Projects

| No. | Project Name | Building Type |

| 1 | Qingdao New Airport Comprehensive Transportation Center and Parking Building Engineering Steel Pipe Column | Truss |

| 2 | Qingdao Blue Silicon Valley Crossing Bridge Steel Structure Engineering | Truss |

| 3 | Uganda in the Ethiopian Medical Park | Door-style Steel Structure |

| 4 | Qatar Logistics Park | Door-style Steel Structure |

| 5 | Dubai Workshop | Door-style Steel Structure |

| 6 | Qingdao Xinuo Co., Ltd Workshop | Door-style Steel Structure |

| 7 | Qingdao Xinxiu Logistics Park 1#, 2#, 3#, 4#, 5# warehouse workshop | Door Steel/Frame |

| 8 | Shandong Oruijin Packaging Project Co., Ltd. Annual production of 1 billion aluminum two-piece cans | Truss |

| 9 | Zhenghe Industrial Co., Ltd. Agricultural Machinery Chain Workshop | Door-style Steel Structure |

| 10 | Qingdao Henry Furniture Co., Ltd. 4#, 5# Workshop Engineering | Frame |

| 11 | Qingdao Thunder Heavy Industry Co., Ltd. Metallurgical Automatic Transmission Equipment Assembly Base Project | Heavy steel lattice column |

| 12 | Qingdao East Asia Industrial Co., Ltd. Integrated Plant Project | Door-style Steel Structure |

| 13 | Qingdao Yujintian Renewable Resources Co., Ltd. 3#, 4# Steel Structure Workshop Engineering | Frame |

| 14 | Sanshandao Gold Mine 8, 000 tons/day exploration and construction combined project | Heavy steel lattice column/truss |

| 15 | Qingdao Puhua Logistics Co., Ltd. | Door-style Steel Structure |

| 16 | SM Zibo Xichuan City Square Multi-storey Steel Structure Installation Project | Frame |

| 17 | Shandong Electric Power Staff Training Base | Truss |

| 18 | Heda Center City Steel Structure Gallery and Modeling Project | Rigid steel bone, heterosexual structure |

| 19 | Qingdao Lisong District Weidong Leke City Steel Corridor Project | Truss, heterosexual structure |

| 20 | Uruguay Grain Depot | Door Steel/Frame |

| 21 | Pakistani Workshop | Door Steel/Frame |

| 22 | Panama Warehouse | Door-style Steel Structure |

| 23 | Uruguay Audi 4s Shop | Frame |

| 24 | Niger Military Aircraft Hangar | Truss |

| 25 | Costa Rica store | Box Beam |

| 26 | Algeria Factory and Office | Frame |

| 27 | Qatar Farming Factory (Chicken House) | Door-style Steel Structure |

| 28 | Ethiopian Factory Villa | Door-style Steel Structure |

| 29 | Venezuelan Villa | Door-style Steel Structure |

| 30 | Brazilian Shipyard | Box Beam |

| 31 | Ecuadorian Farming Factory | Door-style Steel Structure |

| 32 | Pingdu Honghua Rubber Factory Mixing Workshop | Door Steel/Frame |

| 33 | Rizhao Sanbao New Factory Construction Project | Frame |

| 34 | Hisense Logistics Park 1#, 2# Warehouse Workshop | Frame |

| 35 | "JIndi Century City" commercial project (Southern Phase II) project | Grid |

| 36 | Qingdao Expressway Intelligent Traffic Safety System Engineering | Box Beam |

| 37 | Annual production of 200, 000 tons of lightweight glass products | Lattice Column |

| 38 | Qingdao Kano Ceramic Steel Structure Factory | Door-style Steel Structure |

| 39 | Yulong Group Co., Ltd. Warehouse Storage Logistics Construction Project 5#, 6# Warehouse | Door Steel/Frame |

| 40 | Qingdao Baichuan Tongda Machinery Co., Ltd. Workshop | Door-style Steel Structure |

| 41 | Qingdao Hengmai Xinte Energy Technology Co., Ltd. | Door-style Steel Structure |

| 42 | Jimo Zhaolong Door and Window Workshop Steel Structure Engineering | Door-style Steel Structure |

| 43 | Qingdao Tianrui Animal Husbandry Technology Co., Ltd. Workshop Engineering | Door-style Steel Structure |

| 44 | Qingdao Qingping Energy Saving and Environmental Protection Co., Ltd. Workshop | Door-style Steel Structure |

7. Our Service

1. Professional design and engineering team

The full solution for house design. We could make the design for the whole house as per your requirement.

2. Procurement and Manufacture for all material for prefabricated building

We have a professional procurement team to make sure all the materials are with good quality. And our factory operation under ISO standard, to make sure the fabrication works with high technology.

3. Site management & Installation supervision

We could send our engineers to help for the installation supervision, you just need to prepare a team which knows normal construction works will be OK.

8. FAQ

Q1: What are your main products?

A: Our man products have prefab K house, T house, SHS house, H house, container house, light steel structure villa, steel structure warehouse, sentry box, sandwich panel, and other construction materials.

Q2: What will the client provide before factory offers a good quotation?

A: When we receive an inquiry from a client, client please fills the purchasing intention sheet, providing us with information of house dimensions, draft drawing, layout and materials for the prefabricated house. We will design the drawings and offer a competitive quotation with the above information.

Q3: What are the main materials of the prefabricated house?

A: Our prefabricated house materials mainly include light steel structure, sandwich panel, roof tile, door, window, covers, screws and other accessories.

Q4: How you calculate the total area?

A: Industry calculation rule as below:

(1) house area = exterior house length X exterior house width X floor

(2) canopy area=exterior house length X 1/2 X canopy width

(3) staircase area = 4.5 sqm X quantity of staircase

(4) corridor area = exterior house length X corridor width

(5) total area = (1) + (2) + (3) + (4) + (5)

Q5: What drawing of the house will factory supply?

A: Plan drawing, elevation drawing, sectional drawing, foundation drawing, installation drawing.

Q6: How many types of sandwich panel do you have?

A: We have an EPS(polystyrene)sandwich panel, rock wool sandwich panel, and PU(polyurethane)sandwich panel.

The characteristics of your sandwich panels respectively:

1. EPS(polystyrene)sandwich panel: Thickness is 50mm, 75mm, 100mm. EPS volume weight is 80-200Kg/m3, water-proof.

2. Rock wool sandwich panel: Thickness is 50mm, 75mm, 100mm. Rock wool volume weight is 200-400Kg /m3, fire-proof, sound-insulation, heat-preservation.

3. PU(polyurethane)sandwich panel: Thickness is 50mm, 75mm, 100mm. PU volume weight is 150-300/m3 water-proof, fire-proof, heat-proof, heat-insulation, heat-preservation, sound-insulation.

Q7: How many colors do your sandwich panels have?

A: Offwhite, ivory white, blue and red color ect...

9. Customized design is welcome, it would be better if you could provide the following information:

1. Location (where will be built? ) _____country, area

2. Size: Length*width*height _____mm*_____mm*_____mm

3. Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

4. Snow load (max. Snow height) _____kn/m2, _____mm

5. Anti-earthquake _____level

6. Brickwall needed or not If yes, 1.2m high or 1.5m high

7. Thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

8. Door quantity & size _____units, _____(width)mm*_____(height)mm

9. Window quanity & size _____units, _____(width)mm*_____(height)mm