Basic Info.

Model NO.

GDHP-3734

Operation Pressure

Atmospheric Pressure

Operational Method

Continuous

Working Principle

Infrared Heating & Sterilizing

Precision

High Precision

Material

SUS

Voltage

380V 50Hz

Bottle

Glass Bottle

Power

25kw

Output Capacity

1500~2000bph

Transport Package

Wooden Case

Specification

CE ISO GMP

Trademark

GDHP

Origin

Guangzhou, China

HS Code

841920000

Production Capacity

50 Sets/ Month

Product Description

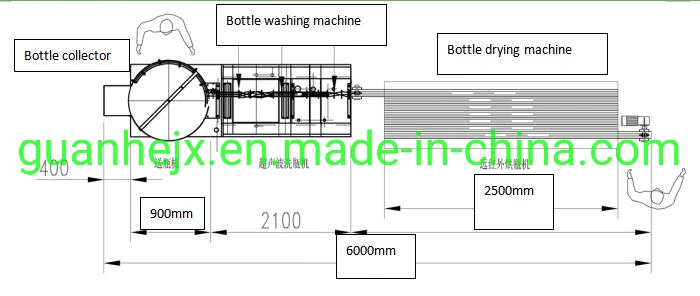

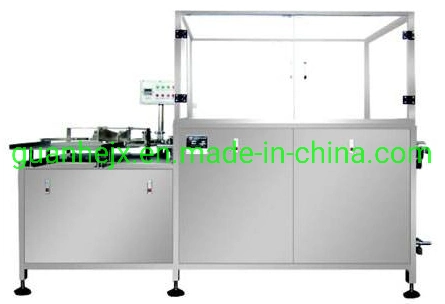

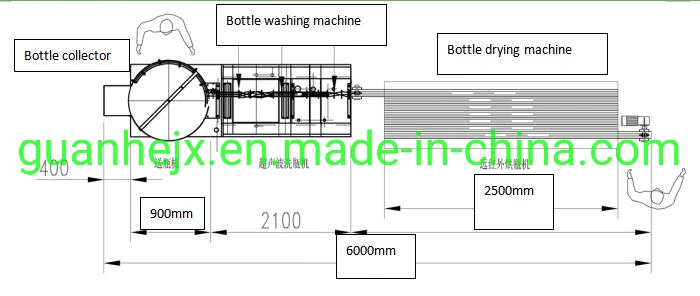

Auto glass vial ultrasonic washing drying machine line

Material: NEW glass bottle

Output capacity:1500BPH

Bottle diameter: D60.7-62.7 mm * H141.9-143.9 mm / D32*H80mm,

1 Bottle collector:

This bottle unscramble is a dynamic worktable with frequency control. Its procedure: put bottles onto round turntable, then turntable rotate to poke bottles onto washing conveying belt.

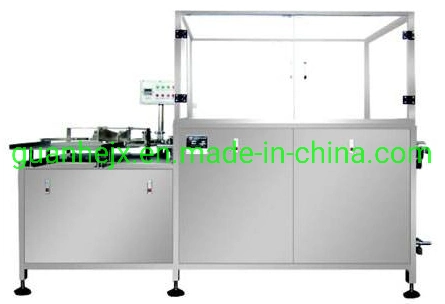

2 Auto ultrasonic washing machine

This machine consists of bottle feeding net conveyor, ultrasonic power tank, bottle feeding pliers, star

This machine consists of bottle feeding net conveyor, ultrasonic power tank, bottle feeding pliers, star

wheel and electric control system. Coarsely washing is conduct by the power of ultrasonic wave to wash the inner and outer wall of the bottles. Finely washing use purified water, WFI and compressed air to wash the inner and outer wall of the bottles alternately.

Washing process: bottles will be washed coarsely in the ultrasonic wave tank through the bottle feeding net conveyor. With the help of screw conveyor and lifting block, the bottles will be rotated by the tunnel with 360 degree.

Characteristic

1 Ultrasonic wave power can wash the wall of the vials thoroughly, cleaning effect is good and the speed can be adjustable by inverter.

2 Water and air come through separate 0.2Μand 0.45Μ filter, clean degree is high. "3 Water,3 air"alternated rinser

3 The washing wfi water can be used as recirculation water, energy-saving and environment-friendly.

4 Water and air pipe separate, avoid cross contamination

5 Water and air low pressure alarm, auto counting function. Suits bottles of different spec, easy to change the change part

Parameter:

Components:

3 Auto vial drying machine

The tunnel includes of three parts, pre-heating, drying part, and cooling. The air device generate heat air strongly brown into bottle. The moisture air auto get out of machine from outlet. It is high efficient, lower energy, and economic.

Advantage:

1, It can be used for various of bottle/can shapes and volumes;

2, Easy construction for easy maintenance;

3, Speed adjustable;

4, the recycle water system will help for reducing water consumption;

5, Conveyor is by high intensity plastic chain belt, is with high intensity, acid resistant, rot resistant and abrasion resistant.

6, Spray angel can be 360°adjustable; spray to every position of bottles averagely.

7, Main motor is with overload protection, can protect conveyor and conveying devices safely. Main driver adopts stepless motor, conveyor speed is changed freely.

Parameter:

Our factory's profile:

Material: NEW glass bottle

Output capacity:1500BPH

Bottle diameter: D60.7-62.7 mm * H141.9-143.9 mm / D32*H80mm,

1 Bottle collector:

This bottle unscramble is a dynamic worktable with frequency control. Its procedure: put bottles onto round turntable, then turntable rotate to poke bottles onto washing conveying belt.

| Applicable standards | 10-15ml | Voltage | 220v 50hz |

| Applicative bottle diameter | φ10-φ100mm | Output power | 0.55kw |

| Applicative bottle height | 55-300mm | Weight | 50kg |

| Production capacity | 0-120bottles /min |

2 Auto ultrasonic washing machine

This machine consists of bottle feeding net conveyor, ultrasonic power tank, bottle feeding pliers, star

This machine consists of bottle feeding net conveyor, ultrasonic power tank, bottle feeding pliers, star wheel and electric control system. Coarsely washing is conduct by the power of ultrasonic wave to wash the inner and outer wall of the bottles. Finely washing use purified water, WFI and compressed air to wash the inner and outer wall of the bottles alternately.

Washing process: bottles will be washed coarsely in the ultrasonic wave tank through the bottle feeding net conveyor. With the help of screw conveyor and lifting block, the bottles will be rotated by the tunnel with 360 degree.

Characteristic

1 Ultrasonic wave power can wash the wall of the vials thoroughly, cleaning effect is good and the speed can be adjustable by inverter.

2 Water and air come through separate 0.2Μand 0.45Μ filter, clean degree is high. "3 Water,3 air"alternated rinser

3 The washing wfi water can be used as recirculation water, energy-saving and environment-friendly.

4 Water and air pipe separate, avoid cross contamination

5 Water and air low pressure alarm, auto counting function. Suits bottles of different spec, easy to change the change part

Parameter:

| Bottle | New glass bottle | Power | 4KW |

| Speed | 1500BPH | Ultrasonic power | 2.5KW |

| Voltage | 380V 50HZ | Air pressure | 0.3 Mpa |

| Quality | ≥99.9% | Weight | 600KG |

| Size | 2100*800*1500 |

Components:

| Ultrasonic generator | Customize | PLC | Siemens |

| Inverter | Siemens | Touch screen | Siemens |

| Turbine Speed reducer | China | Low-voltage electricals | French Schneider |

| Water pump | China | Power amplifier module | Japan Mitsubishi |

| magnetic valve | China | Motor | China |

3 Auto vial drying machine

The tunnel includes of three parts, pre-heating, drying part, and cooling. The air device generate heat air strongly brown into bottle. The moisture air auto get out of machine from outlet. It is high efficient, lower energy, and economic.

Advantage:

1, It can be used for various of bottle/can shapes and volumes;

2, Easy construction for easy maintenance;

3, Speed adjustable;

4, the recycle water system will help for reducing water consumption;

5, Conveyor is by high intensity plastic chain belt, is with high intensity, acid resistant, rot resistant and abrasion resistant.

6, Spray angel can be 360°adjustable; spray to every position of bottles averagely.

7, Main motor is with overload protection, can protect conveyor and conveying devices safely. Main driver adopts stepless motor, conveyor speed is changed freely.

Parameter:

| Nodel | GHHX-3 |

| Voltage | 380V 50HZ 3P |

| Power | 20KW |

| Size | 2500mm*800mm*1680mm |

| Temperature | 100-250,AI Omron temperature control |

| Conveyor | Famous Delta frequency converter |

| Low voltage electric | France Schneider |

Our factory's profile: