- Overview

- Product Description

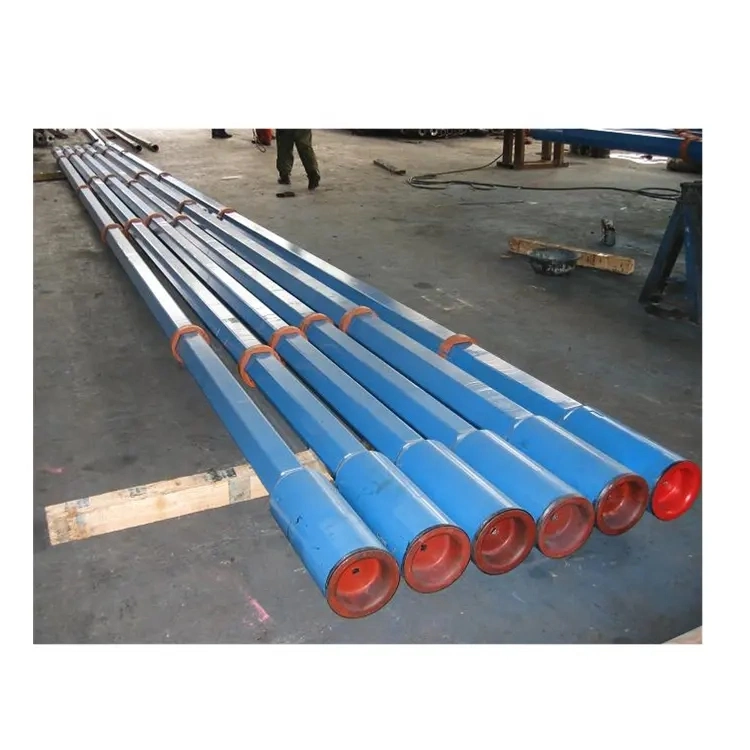

- Detailed Photos

- Our Advantages

- Packaging & Shipping

- Company Profile

- Certifications

- FAQ

Basic Info.

Product Description

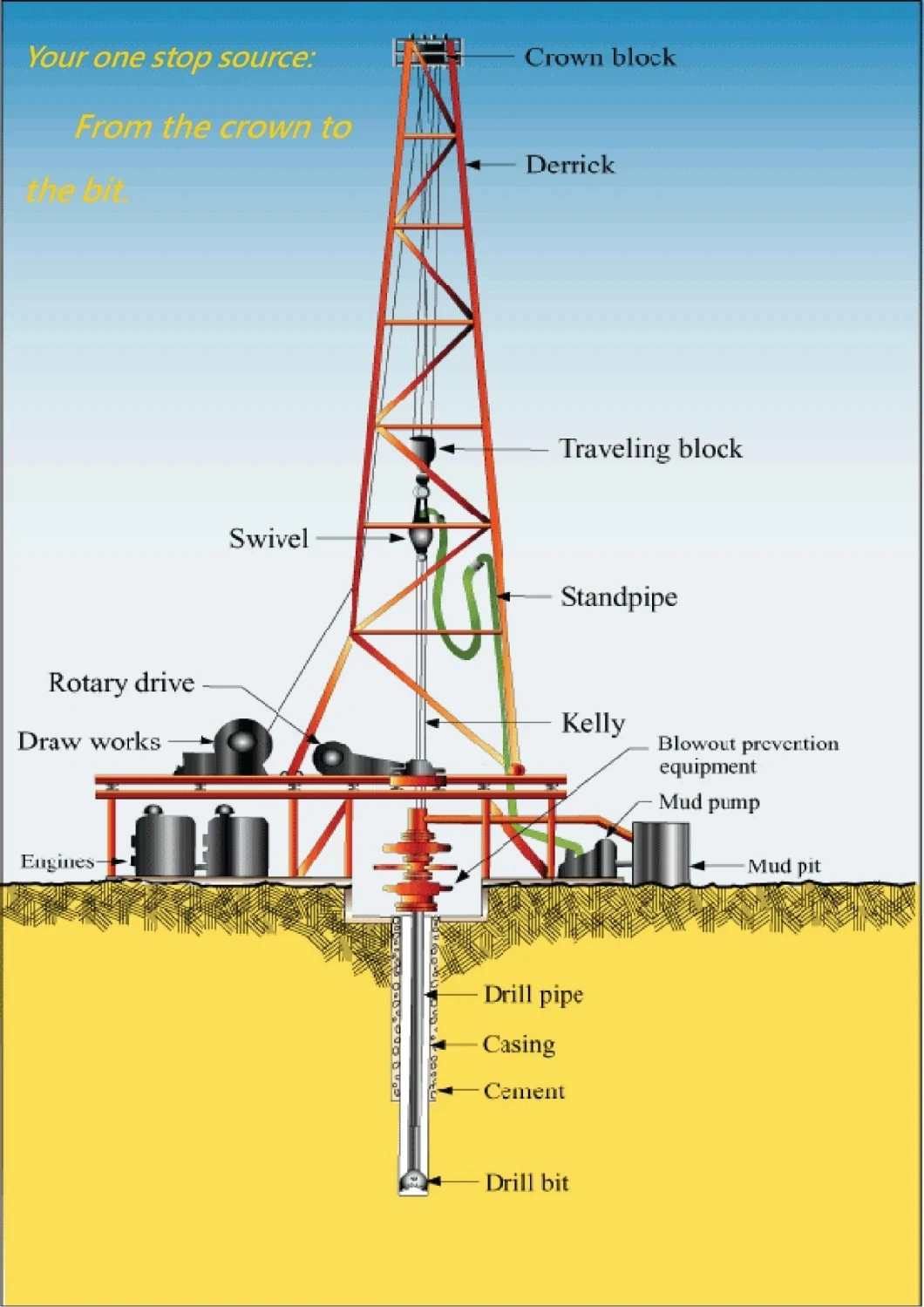

Kelly is the drive part of whole drill stem, it has two types, square kelly and hexagonal kelly and all of them are manufactured comfort to API Spec7-1 and SY/T6509-2000 criterion.

Our Square& Hexagonal kelly are made from AISI 4145H modified alloy bars that are quenched and tempered full length. After such heat treatment, its brinell hardness can reach 285-341. Kelly's end, drive cross-section and joint are all processed and tested comform to API criterion.The formulated process can ensure that the misalignment of the hole reaches the standard wall thickness. Kelly bars are manufactured according to API-7-1 Spec.

The Main Technical Specification of Kelly ( Square& Hexagonal )

Norminal Size (in) | Length(ft) | Top Upset Joint | Bottom Upset Joint | Bore D | Drive Section | |||

API BOX Thread Left Hand | Du | Right Hand Connections | DL | Across Corners | Across Flates | |||

3-1/2 | 40 | 6 5/8REG | 7 3/4 | NC38(3 1/2IF) | 4 3/4 | 2 1/4 | 4.437 | 3 1/2 |

4-1/4 | 40 | 6 5/8REG | 7 3/4 | NC46 (41F) NC50(4 1/2IF) | 6~6 3/8 6 1/8~6 3/8 | 2 13/16 | 5.500 | 4 1/4 |

5-1/4 | 40 | 6 5/8REG | 7 3/4 | NC50 5 1/2FH | 7 | 3 1/4 | 6.750 | 5 1/4 |

6 | 40 | 6 5/8REG | 7 3/4 | NC50 | 7 3/4 | 3 1/2 | 7.625 | 6 |

About us

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T and Western Union are the most usual ways we are using.

3) What's the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pr -epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25days if we don't have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

4)How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

5)How do you check all the goods in the production line?

A: We have spot inspection and finished product inspection. We check the goods when they go into next step production procedure.