- Overview

- FAQ

Basic Info.

Product Description

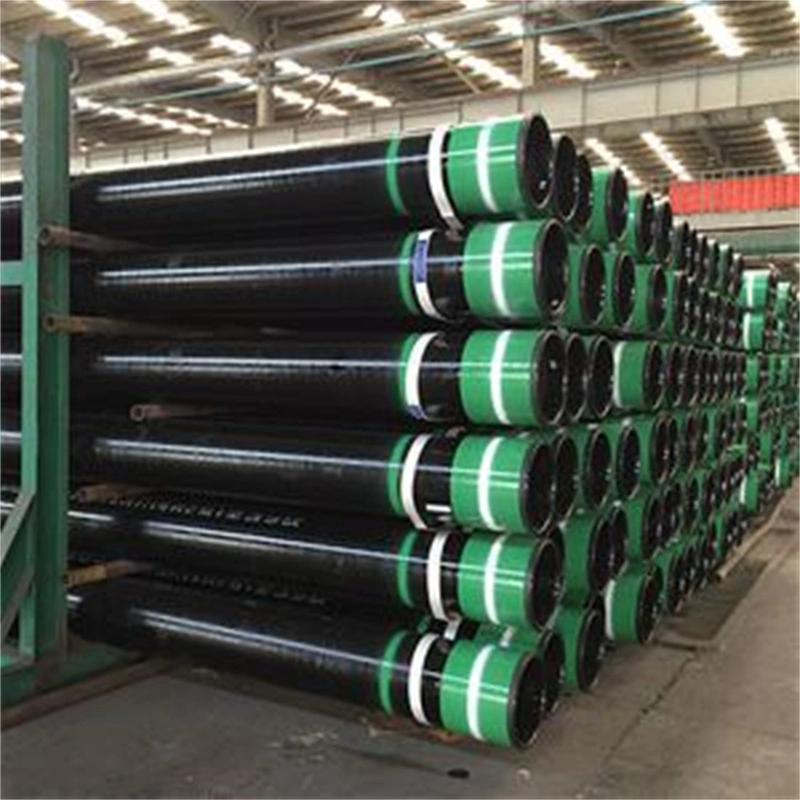

Product name:API-5CT Seamless Casing

Material: 34CrMo4,H40,J55, K55, N80,L80,M65,C90,T95,P110,Q125

Standard: API 5CT Grade: J55 K55

Outer Diameter: 219.08-762mm Thickness: 6.71 - 30 mm

Technique: Cold Drawn/Hot Rolled Application: Oil Pipe

Secondary Or Not:Non-secondary Place of Origin: China (Mainland)

Certification: API Section Shape: Round

Surface Treatment:Black,varnish Special Pipe: API Pipe

Alloy Or Not: Is Alloy and Carbon Steel

Packaging & Delivery

Packaging Details: Seaworthy, Steel Shelf, Iron Pallet or as per customer's requirement

Delivery Times:20-55 days

Chemical compositions of casing pipe

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| Q125 | ≤0.35 | ------------- | ≤1.35 | ≤0.020 | ≤0.010 | ≤1.50 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Mechanical properties of casing pipe

| Grade | Type | Total elongation under load (%) | Yield strength (min)Mpa | Yield strength (max)Mpa | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max (HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | All | 0.65 | 862 | 1034 | 931 | - | - |

Casing Pipe Manufacturing Process:

Steel ingot heating → hydraulic punching → reheating → extension → periodic rolling → reheating → sizing → cooling → straightening → pipe cutting → inspection

1. An annular heating furnace is required for ingot heating;

2. Punching and reheating with hydraulic press;

3. The oil casing plant uses a two-roller guide plate extension machine for extension;

4. Re-use a disc heating furnace for periodic rolling, and use a non-entry furnace for reheating, cooling, straightening, pipe cutting, and inspection.

Q1. How can I request a product sample?

A. The samples are free. We are also responsible for the freight of samples. Please send your adress and your telephone namber by email.

Q2. How can I request a product catalog?

A The hard copies of cataloges are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q3. What's your payment terms?

A One is T/T 30% before production and 70% against copy of B/L; the other is irrevocable L/C 100% at sight.

Q4. What's your trade terms?

A FOB, CNF (CFR), CIF, EXW

Q5. When can i receive the goods?

A 20 days of production lead time from receive the down payment, remaining time depends on where the destination port located.

Q6. How long is the quality guarantee?

A. All of our product have a period of quality guarantee since time of shipment. please contact us for more details.