Basic Info.

Product Description

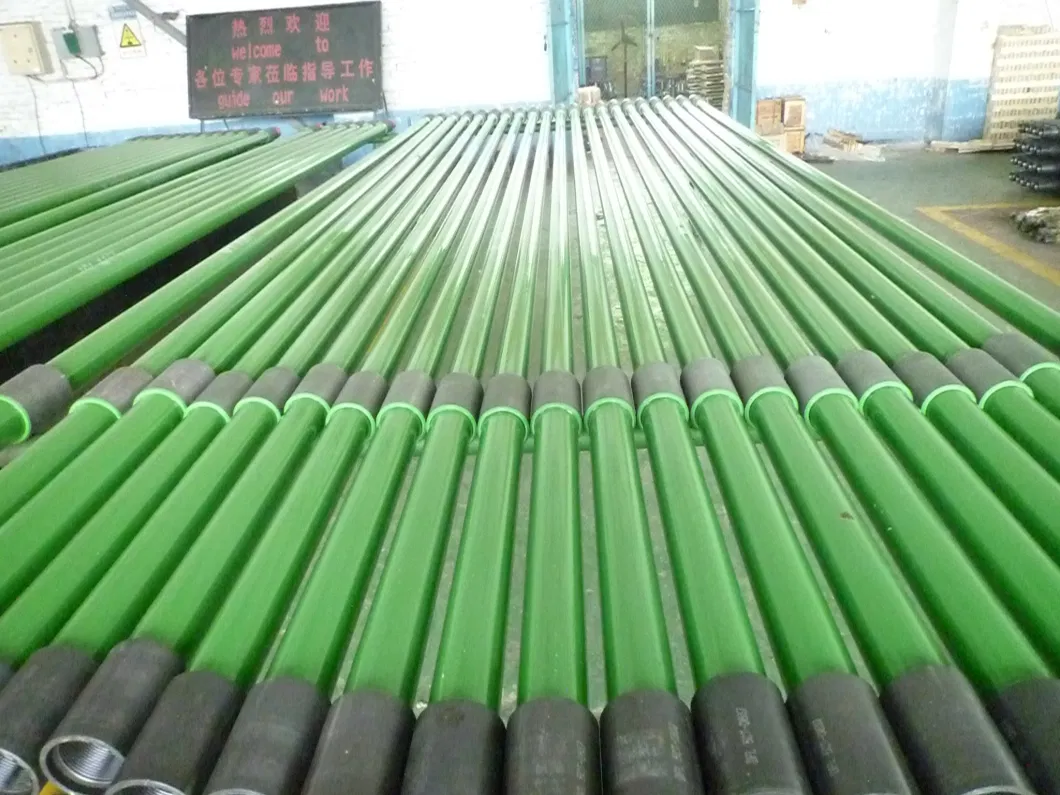

Description:

1.Production technology:Plain pipe-end upsetting-Austenite

treatment-Quenching-Tempering-straightening-(Non-Destructive Testing)-Threading-Thread inspection-coupling

MPI-phosphating-Coupling make up-Drifting-Hydrostatic

testing-Measuring&Weight-Marking&Stenciling-Coating-Packing Casing and tubing-Transportation

2.Executive standards:API spec 5CT,API spec 5B

3.Specification range:2-3/8",2-7/8",3-1/2",4",4-1/2"

WT:4.24-16mm

4.Materials:H40,J55,K55,N80,L80,C90,T95 and P110

5.T&C:EUE,NU,IJ and Special Coupled.

6.Length:R1,R2,R3

7.Testing:NDT etc related rules of API 5CT and 5B

8.Packing:By bundles,seaworthy packing.

9.Application:

Oil Tubing is widely used for transporting crude oil and natural gas to surface after drilling,which also bears pressurefrom exploration.

Technical Parameters of Oil Tubing:

| Labels | Outside Diameter | Nominal Linear Masses a,b | Wall Thickness | Type of End Finish | |||||||||||

| 1 | 2 | Non-upset T&C | Ext.Upset T&C | Integ. Joint | |||||||||||

| NU T&C | EU T&C | IJ | D (mm) | kg/m | kg/m | kg/m | t (mm) | H40 | J55 | L80 R95 | N80-1, Q | C90 | T95 | P110 | |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.050 1.050 | 1.14 1.48 | 1.20 1.54 | - - | 26.67 26.67 | 1.70 2.20 | 1.79 2.29 | - - | 2.87 3.91 | PNU PU | PNU PU | PNU PU | PNU PU | PNU PU | PNU PU | PU |

| 1.315 1.315 | 1.70 2.19 | 1.80 2.24 | 1.72 - | 33.40 33.40 | 2.53 3.26 | 2.68 3.33 | 2.56 - | 3.38 4.55 | PNUI PU | PNUI PU | PNUI PU | PNUI PU | PNUI PU | PNUI PU | PU |

| 1.660 1.660 1.660 | 2.09 2.30 3.03 | - 2.40 3.07 | 2.10 2.33 - | 42.16 42.16 42.16 | - 3.42 4.51 | - 3.57 4.57 | 3.13 3.47 - | 3.18 3.56 4.85 | PI PNUI PU | PI PNUI PU | - PNUI PU | - PNUI PU | - PNUI PU | - PNUI PU | PU |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | - 2.90 3.73 - - | 2.40 2.76 - - - | 48.26 48.26 48.26 48.26 48.26 | - 4.09 5.43 6.58 7.66 | - 4.32 5.55 - - | 3.57 4.11 - - - | 3.18 3.68 5.08 6.35 7.62 | PI PNUI PU - - | PI PNUI PU - - | - PNUI PU P P | - PNUI PU - - | - PNUI PU P P | - PNUI PU P P | - PNUI PU - - |

| 2.063 2.063 | 3.24 4.50 | - - | 3.25 - | 52.40 52.40 | - - | - - | 4.84 - | 3.96 5.72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2 3/8 2 3/8 2 3/8 2 3/8 2 3/8 | 4.00 4.60 5.80 6.60 7.35 | - 4.70 5.95 - 7.45 | - - - - - | 60.32 60.32 60.32 60.32 60.32 | 5.95 6.85 8.63 9.82 10.94 | - 6.99 8.85 - 11.09 | - - - - - | 4.24 4.83 6.45 7.49 8.53 | PN PNU - - - | PN PNU - - - | PN PNU PNU P PU | PN PNU PNU - - | PN PNU PNU P PU | PN PNU PNU P PU | PN PNU PNU - - |

| 2 7/8 2 7/8 2 7/8 2 7/8 2 7/8 2 7/8 | 6.40 7.80 8.60 9.35 10.50 11.50 | 6.50 7.90 8.70 9.45 - - | - - - - - - | 73.02 73.02 73.02 73.02 73.02 73.02 | 9.52 11.61 12.80 13.91 15.63 17.11 | 9.67 11.76 12.95 14.06 - - | - - - - - - | 5.51 7.01 7.82 8.64 9.96 11.18 | PNU - - - - - | PNU - - - - - | PNU PNU PNU PU P P | PNU PNU PNU - - - | PNU PNU PNU PU P P | PNU PNU PNU PU P P | PNU PNU PNU - - - |

| 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 3 1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | - 9.30 - 12.95 - - - | - - - - - - - | 88.90 88.90 88.90 88.90 88.90 88.90 88.90 | 11.46 13.69 15.18 18.90 21.28 23.07 25.30 | - 13.84 - 19.27 - - - | - - - - - - - | 5.49 6.45 7.34 9.52 10.92 12.09 13.46 | PN PNU PN - - - - | PN PNU PN - - - - | PN PNU PN PNU P P P | PN PNU PN PNU - - - | PN PNU PN PNU P P p | PN PNU PN PNU p p p | - PNU - PNU - - - |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | - 11.00 - - - - | - - - - - - | 101.60 101.60 101.60 101.60 101.60 101.60 | 14.14 - 19.64 23.96 28.13 33.04 | - 16.37 - - - - | - - - - - - | 5.74 6.65 8.38 10.54 12.70 15.49 | PN PU - - - - | PN PU - - - - | PN PU P P P P | PN PU - - - - | PN PU P P P P | PN PU P P p P | - - - - - - |

| 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 4 1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 - - - - - - | - - - - - - - | 114.30 114.30 114.30 114.30 114.30 114.30 114.30 | 18.75 22.62 25.30 28.13 32.00 35.27 38.84 | 18.97 - - - - - - | - - - - - - - | 6.88 8.56 9.65 10.92 12.70 14.22 16.00 | PNU - - - - - - | PNU - - - - - - | PNU P P P P P P | PNU - - - - - - | PNU P P P P P P | PNU P P P P P P | - - - - - - - |

| Note: P=Plain-end, N=Non-upset threaded and coupled, U=External upset threaded and coupled, I=Integral joint. | |||||||||||||||

| a. Nominal linear masses (Columns 6,7,and 8) are shown for information only. b. The densities of martensitic chromium steels (L80 types 9Cr and 13Cr) are different from carbon steels. The masses shown are therefore not accurate formartensitic chromium steels. A mass correction factor of 0.989 may be used. | |||||||||||||||

| Note: other premium connection shall be provided as per customer requirements. | |||||||||||||||