Basic Info.

Model NO.

ZR-430

Alloy

Alloy

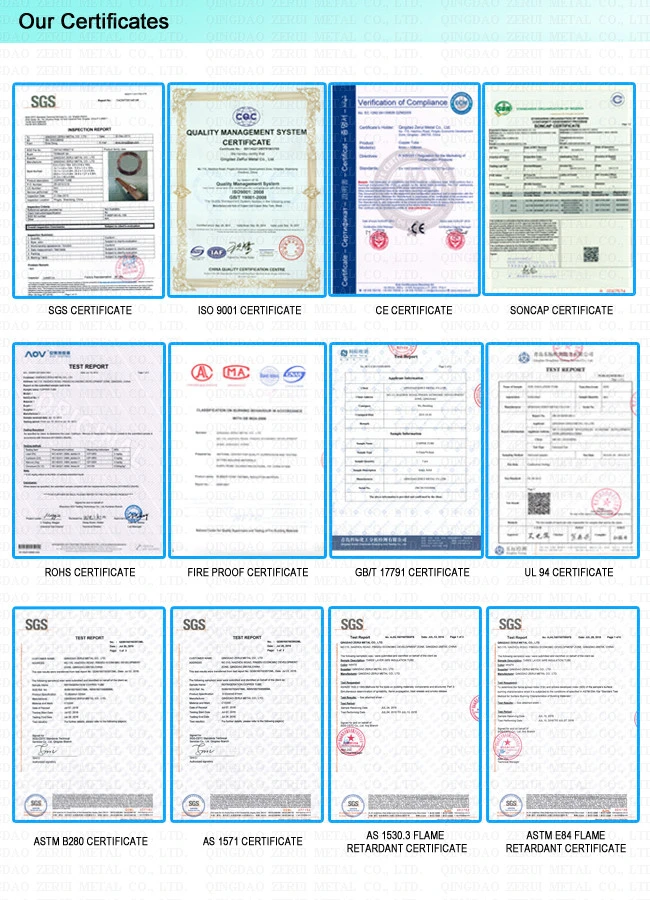

Certification

CE, ISO, RoHS, SGS

Standard

En 12449

Grade

H70

State

Hard

Customized

Customized

Color

Yellow

Thickness

From 0.4mm to 4.0mm

Length

3m, 4m, 5m, 5.5m, 6m

Hardness

H80

Copper

70%

Zinc

30%

Transport Package

Wooden Cases

Specification

6.35-70.0mm

Trademark

ZeRui

Origin

Qingdao, China

HS Code

74112190

Production Capacity

1000 Tons Per Month

Packaging & Delivery

Package Size

110.00cm * 110.00cm * 20.00cm

Package Gross Weight

15.600kg

Product Description

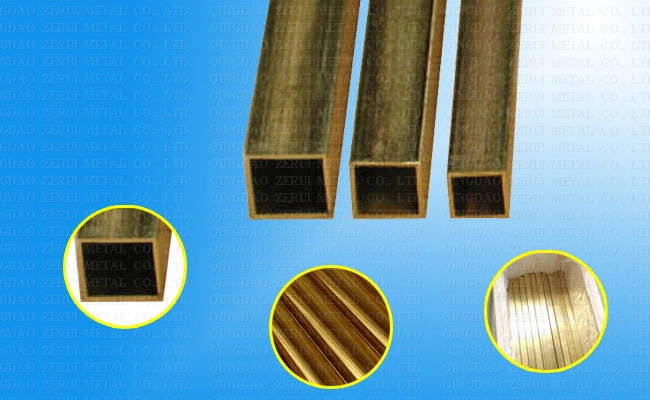

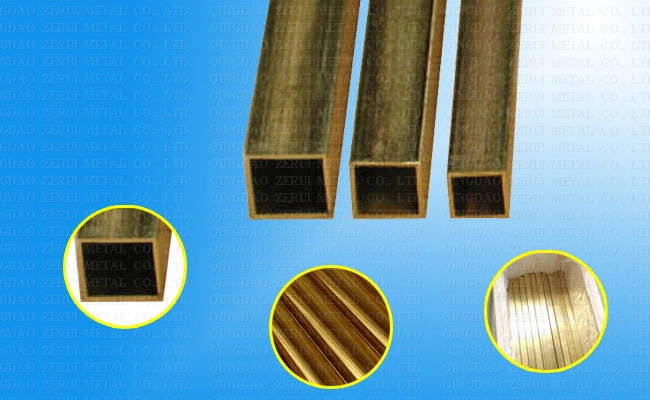

20x20x1mm solid decorative square brass tubing

1.

Production Specifications:

Square and rectangular brass tube is corrosion-resistant and malleable. It is well designed for many decorative, architectural

and industrial structural applications.

Our square and rectangular brass tube is available in size from 1/4" to 2" (from 6.35mm to 50.80mm). The range of brass tube

is available as hard temper, half hard temper. The square and rectangular brass tubes are manufactured according to

ASTM B135, ASTM B251 standard.

Product Pictures:

Chemical Composition & Mechanical Property

Standard & Alloy

Size Range (mm):

2.

3.

4.

5.

6.

1.

Production Specifications:

Square and rectangular brass tube is corrosion-resistant and malleable. It is well designed for many decorative, architectural

and industrial structural applications.

Our square and rectangular brass tube is available in size from 1/4" to 2" (from 6.35mm to 50.80mm). The range of brass tube

is available as hard temper, half hard temper. The square and rectangular brass tubes are manufactured according to

ASTM B135, ASTM B251 standard.

Product Pictures:

Chemical Composition & Mechanical Property

| Brass Tubing Alloy | Chemical Composition | Temper | Mechanical Property | ||||

| Copper % | Lead % | Iron % | Zinc % | Tensile Strength MPa | Elongation % | ||

| C22000 | 89.0-91.0 | ≤0.05 | ≤0.05 | remainder | soft | ≥225 | ≥35 |

| 1/2 Hard | ≥275 | ≥15 | |||||

| Hard | ≥360 | / | |||||

| C23000 | 84.0-86.0 | ≤0.05 | ≤0.05 | remainder | soft | ≥275 | ≥35 |

| 1/2 Hard | ≥305 | ≥20 | |||||

| Hard | ≥390 | / | |||||

| C26000 | 68.5-71.5 | ≤0.07 | ≤0.05 | remainder | soft | ≥275 | ≥45 |

| 1/2 Hard | ≥375 | ≥20 | |||||

| Hard | ≥450 | / | |||||

| C27000 | 63.0-68.5 | ≤0.10 | ≤0.07 | remainder | soft | ≥295 | ≥40 |

| 1/2 Hard | ≥375 | ≥20 | |||||

| C27200 | 62.0-65.0 | ≤0.07 | ≤0.07 | remainder | |||

| Hard | ≥450 | / | |||||

| C28000 | 59.0-63.0 | ≤0.30 | ≤0.07 | remainder | soft | ≥315 | ≥35 |

| 1/2 Hard | ≥375 | ≥15 | |||||

| Hard | ≥450 | / | |||||

Standard & Alloy

| ASTM B135 | EN 12449 | JIS H3300 | GB/T 1527 |

| C22000 | CuZn10 | C2200 | H90 |

| C23000 | CuZn15 | C2300 | H85 |

| C26000 | CuZn30 | C2600 | H70 |

| C27000 | CuZn36 | C2700 | H65 |

| C27200 | CuZn37 | / | H63 |

| C28000 | / | C2800 | H62 |

Size Range (mm):

| W.T. O.D. | 0.5-0.6 | 0.6-0.8 | 0.8-1.0 | 1.0-1.2 | 1.2-1.5 | 1.5-2.0 | 2.0-3.0 | 3.0-4.0 |

| 6.35-12.7 | √ | √ | √ | √ | √ | |||

| 12.7-19.05 | √ | √ | √ | √ | √ | √ | ||

| 19.05-25.4 | √ | √ | √ | √ | √ | √ | ||

| 25.4-34.93 | √ | √ | √ | √ | √ | √ | ||

| 34.93-50.8 | √ | √ | √ | √ | √ | |||

| 50.8-70.0 | √ | √ | √ | √ | √ |

2.

3.

4.

5.

6.